As global energy demand grows and sustainability becomes a top priority, decentralized renewable energy systems are gaining momentum. Among these solutions, biogas combined heat and power (CHP) plants play a critical role by converting organic waste into both electricity and heat efficiently, offering local communities and industries a reliable, low-carbon energy source.

What is a Biogas CHP Plant?

A biogas CHP plant captures energy from biogas—produced through the anaerobic digestion of organic waste—and converts it into electricity and heat simultaneously. Unlike conventional power plants that may waste heat, CHP systems make full use of the energy content in biogas, achieving efficiency levels of 70-90%. This dual energy output makes them ideal for decentralized applications, such as farms, small industries, or community energy projects, where both power and thermal energy are required on-site.

Benefits of Decentralized Biogas CHP Systems

Energy Independence: Localized generation reduces reliance on the main power grid.

Sustainable Waste Management: Organic waste from agriculture, food processing, and municipal sources is converted into energy instead of polluting landfills.

High Efficiency: Heat recovery allows for applications such as heating greenhouses, buildings, or water.

Reduced Carbon Footprint: By substituting fossil fuels, biogas CHP plants help communities and industries lower greenhouse gas emissions.

Ensuring Optimal Performance with Monitoring Equipment

The efficiency and safety of a biogas CHP plant depend heavily on the quality of the biogas produced. Gas composition directly affects engine performance and emissions, making monitoring a vital component of modern systems.

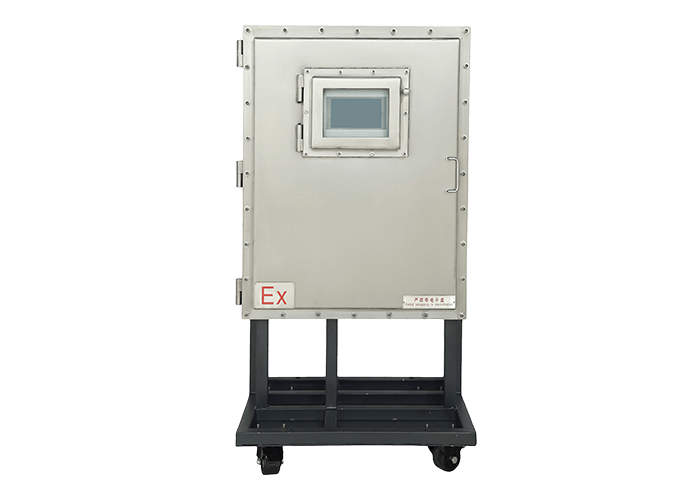

Monitoring equipment such as biogas analyzers ensures consistent performance. These analyzers use advanced photoelectric sensing principles to detect and measure critical gases including methane (CH4), oxygen (O2), carbon dioxide (CO2), and hydrogen sulfide (H2S). For example, the OLGA2000 biogas online monitoring system can be widely deployed in landfill biogas power plants, petrochemical industries, coal mines, and other applications. It also supports remote data transmission, enabling operators to monitor and manage biogas quality and system performance from anywhere, ensuring both safety and efficiency.

the OLGA2000 biogas online monitoring system

Applications and Future Potential

Biogas CHP plants are versatile and can be integrated into various sectors:

Agriculture: Using manure and crop residues to generate electricity and heating.

Food Processing Industries: Converting organic waste into energy for on-site use.

Municipal Waste Management: Reducing landfill waste while producing local energy.

As renewable energy policies expand, the potential for decentralized biogas CHP plants grows. These systems offer a scalable solution for rural electrification, industrial energy self-sufficiency, and community-based renewable energy projects.

Biogas CHP plants are an essential component of decentralized renewable energy systems, combining waste management with energy generation. With modern monitoring tools like the OLGA2000 biogas analyzer, operators can ensure optimal performance, safety, and efficiency. By harnessing the power of local organic waste, these plants empower communities and industries to adopt cleaner, more sustainable energy solutions while contributing to a circular economy.