As the world shifts toward low-carbon, circular economies, the need for effective and sustainable waste-to-energy solutions becomes more urgent. One standout example in the United Kingdom is Warrens Emerald Biogas, a pioneering facility that demonstrates how organic waste can be transformed into clean, renewable energy—reducing landfill dependence while generating electricity, heat, and valuable biofertilizers.

This article explores how Warrens Emerald Biogas is redefining waste management through anaerobic digestion, and what lessons other regions and industries can learn from their approach.

About Warrens Emerald Biogas

Located in Newton Aycliffe, County Durham, Warrens Emerald Biogas is one of the UK’s leading anaerobic digestion (AD) facilities dedicated to processing food waste. Since its establishment, the plant has diverted thousands of tonnes of commercial and household food waste from landfills and transformed it into renewable energy and digestate, helping businesses and local authorities meet environmental targets.

With the capacity to process over 115,000 tonnes of food waste per year, the facility generates up to 3 megawatts of electricity—enough to power thousands of homes. It also produces nutrient-rich digestate, which is used as a biofertilizer on local farmland, closing the loop between waste and agriculture.

The Waste-to-Energy Process

At the heart of Warrens Emerald Biogas is the anaerobic digestion process, where microorganisms break down organic waste in the absence of oxygen. The result is two valuable outputs:

Biogas: A combustible mix primarily composed of methane (CH₄) and carbon dioxide (CO₂), used to generate electricity and heat.

Digestate: A stabilized organic slurry that can be applied to land as a natural fertilizer.

This clean process not only extracts energy from waste but also reduces greenhouse gas emissions by capturing methane that would otherwise be released from landfills.

The Role of Technology in Biogas Monitoring

Accurate monitoring is critical to ensure the safety, efficiency, and consistency of biogas production.

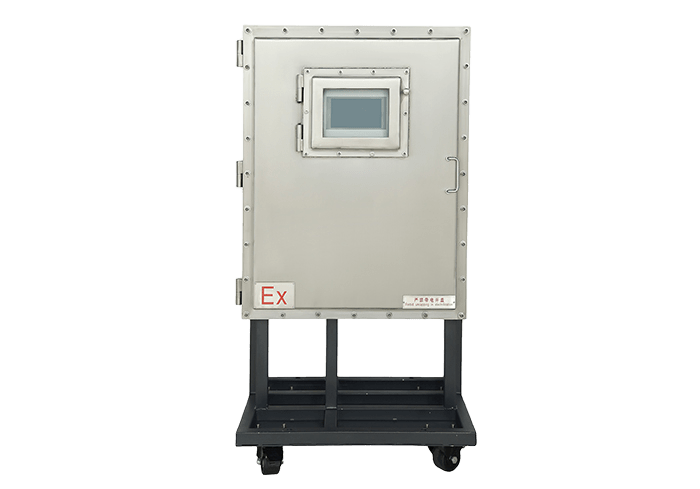

During the biogas production process, the required equipment is a biogas analyzer, which uses advanced photoelectric sensing principles to detect and analyze methane (CH₄), oxygen (O₂), carbon dioxide (CO₂), hydrogen sulfide (H₂S), and other gases. For example, the OLGA2000 Online Biogas Monitoring System can be widely used in gas monitoring in landfill gas power plants, petrochemicals, coal mines, and other scenarios, and can realize remote data transmission.

OLGA2000 biogas analyzer

Warrens Emerald Biogas employs such technologies to:

Maintain optimal digester performance

Monitor gas purity for power generation

Detect harmful gases like H₂S, which can damage equipment

Ensure regulatory compliance and environmental safety

By integrating real-time gas analysis and remote data monitoring, the facility maximizes uptime, gas yield, and operational safety.

Key Lessons from Warrens Emerald Biogas

1. Food Waste Is a Valuable Resource

Rather than sending food waste to landfills, Warrens Emerald Biogas proves that it can be a consistent and sustainable source of energy—while also reducing methane emissions and environmental impact.

2. Technology Enhances Efficiency

Advanced monitoring systems like OLGA2000 ensure that operations remain efficient, safe, and data-driven. Continuous insight into gas composition allows for rapid response to process changes or anomalies.

3. Partnerships Drive Circularity

The success of the facility depends on strong relationships with food manufacturers, local councils, and farmers. Waste producers benefit from responsible disposal, while local agriculture gains access to low-cost organic fertilizer.

4. Anaerobic Digestion Is Scalable

The facility demonstrates that AD can work at commercial scales, processing large volumes of waste and delivering significant environmental and energy benefits.

5. Education and Engagement Are Essential

Warrens Emerald Biogas invests in community outreach and education, raising awareness of the value of food waste and promoting sustainable behavior across supply chains and households.

Environmental and Economic Impact

By diverting tens of thousands of tonnes of waste from landfills annually, Warrens Emerald Biogas:

Reduces methane emissions (a potent greenhouse gas)

Offsets fossil fuel use through renewable power generation

Provides sustainable fertilizer to local farms

Supports job creation in the green energy sector

This makes it a key player in helping the UK meet its Net Zero goals and a model for similar projects around the world.

Warrens Emerald Biogas shows that waste is not just a problem—it’s an opportunity. By combining smart technology, strategic partnerships, and circular thinking, the facility is unlocking the full potential of organic waste to produce clean energy and valuable resources.

Facilities around the world can take inspiration from its success, especially in the use of modern monitoring systems like OLGA2000 to ensure optimal biogas production. As more regions embrace sustainable energy from waste, the Warrens Emerald Biogas story stands as a powerful example of innovation, responsibility, and impact.