Biogas plants offer a powerful solution to two major global challenges: waste management and renewable energy generation. By transforming organic waste into usable energy, biogas systems support sustainability in agriculture, municipal waste treatment, and industrial processes. At the heart of biogas production are the gases generated during anaerobic digestion—a process where microorganisms break down organic matter in the absence of oxygen. Understanding and managing these gases is essential to ensuring efficiency, safety, and environmental compliance in biogas plant operations.

The Anaerobic Digestion Process

Anaerobic digestion (AD) is a complex biochemical process that occurs in four main stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. During these stages, organic material such as agricultural waste, food scraps, sewage sludge, or animal manure is converted into biogas and digestate (a nutrient-rich slurry).

The primary product—biogas—is a mixture of several gases, with the most significant being:

Methane (CH₄)

Carbon Dioxide (CO₂)

Hydrogen Sulfide (H₂S)

Oxygen (O₂) (usually trace amounts)

Nitrogen (N₂) and other trace gases

Each of these gases plays a unique role in plant operations, and their proportions must be carefully monitored and managed.

Key Gases and Their Roles in Biogas Plants

- Methane (CH₄): The Energy Carrier

Methane is the main energy component in biogas, typically making up 50–70% of the total gas volume. The higher the methane concentration, the greater the calorific value of the biogas. This gas can be combusted to generate electricity and heat or upgraded to biomethane for use in natural gas grids or as vehicle fuel.

Operators must continuously monitor methane levels to evaluate the performance of the digestion process and optimize gas yield.

- Carbon Dioxide (CO₂): A Process Indicator

Carbon dioxide typically comprises 30–50% of raw biogas. While it does not contribute to energy generation, CO₂ levels provide insight into the balance of microbial activity. Excessive CO₂ may indicate suboptimal digestion conditions or contamination.

Removing CO₂ is essential when upgrading biogas to biomethane, a process that enhances the methane concentration to over 95%.

- Hydrogen Sulfide (H₂S): A Corrosive Hazard

Even in small amounts, hydrogen sulfide is highly corrosive and toxic. It is formed when sulfur-containing compounds in feedstock are broken down during digestion. H₂S corrodes metal pipes, engines, and gas storage units, and it poses health risks to workers.

Effective desulfurization systems, such as activated carbon filters or biological scrubbers, are critical for reducing H₂S content and protecting equipment and personnel.

- Oxygen (O₂) and Nitrogen (N₂): Indicators of Air Intrusion

Ideally, biogas production should occur in a completely anaerobic (oxygen-free) environment. The presence of oxygen and nitrogen often indicates air intrusion, which can disrupt the anaerobic digestion process and lead to safety risks, including explosive gas mixtures.

Detecting O₂ and N₂ helps operators maintain system integrity and prevent operational inefficiencies.

Importance of Gas Monitoring and Analysis

Monitoring gas composition is essential for:

Optimizing gas production and energy output

Preventing equipment damage and health hazards

Meeting environmental and regulatory standards

Ensuring the safety of workers and infrastructure

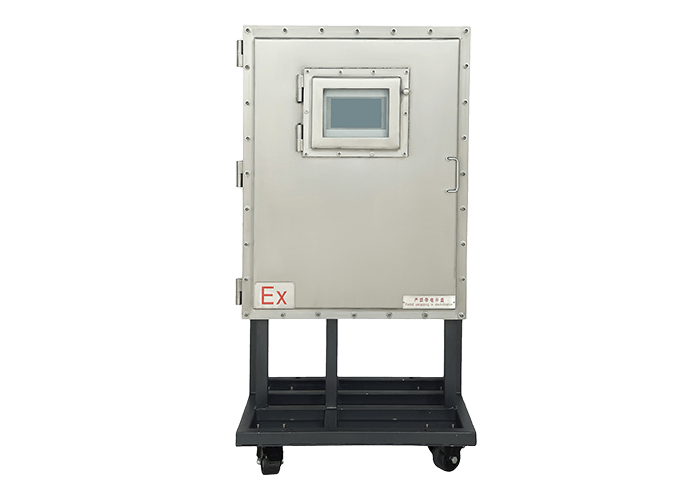

Advanced biogas analyzers, like the OLGA2000 online monitoring system, are widely used in modern biogas plants. These devices utilize photoelectric or infrared sensor technologies to continuously track levels of CH₄, CO₂, O₂, H₂S, and other gases, allowing for real-time process control and early fault detection.

Online Biogas Analyzer OLGA2000

The conversion of waste into energy through biogas technology is a sustainable and practical solution for many industries and communities. However, the efficiency and safety of a biogas plant depend heavily on understanding and managing the gases produced. By investing in robust gas monitoring systems and maintaining optimal operational conditions, biogas operators can maximize energy output, minimize environmental impact, and contribute to a cleaner, more resilient energy future.