As the world moves toward sustainable energy solutions, traditional renewable fuels like gobar gas methane are gaining renewed attention. Gobar gas, commonly produced from cow dung and other animal waste, has been used for decades in rural areas as a cheap and eco-friendly fuel. Today, advancements in biogas technology are modernizing gobar gas systems, making them more efficient and expanding their applications beyond just household cooking.

What is Gobar Gas?

Gobar gas is a type of biogas primarily produced from the anaerobic digestion of cow dung (gobar). The breakdown of organic matter by bacteria in an oxygen-free environment results in a gas mixture rich in methane (CH₄), which can be used as a fuel for cooking, heating, and power generation.

Composition of Gobar Gas

- Methane (CH₄): 50-75% – The main fuel component responsible for energy generation.

- Carbon dioxide (CO₂): 25-45% – A byproduct of the digestion process.

- Hydrogen sulfide (H₂S), nitrogen (N₂), and water vapor in small quantities.

Because of its high methane content, gobar gas is a cleaner and more sustainable alternative to wood, coal, and liquefied petroleum gas (LPG).

How is Gobar Gas Methane Produced?

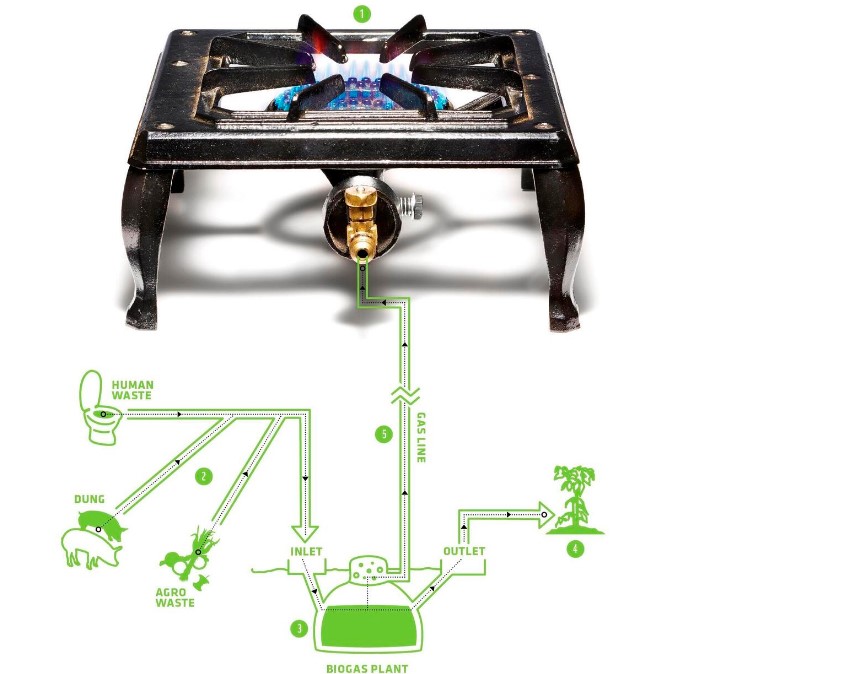

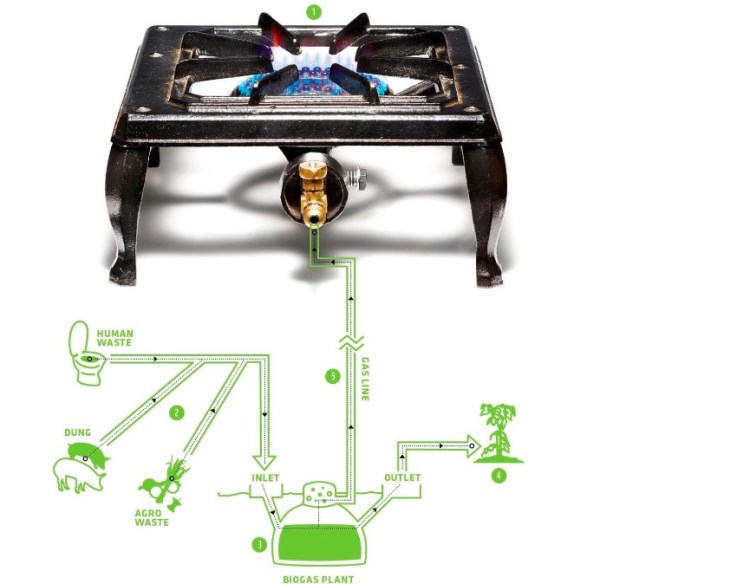

The production of gobar gas follows the anaerobic digestion process, where bacteria break down organic matter in the absence of oxygen inside a biogas digester. The main steps include:

1. Collection of Raw Materials

Cow dung and other animal manure are mixed with water to form a slurry.

Agricultural waste, food scraps, and plant residues can also be added to increase gas yield.

2. Anaerobic Digestion in a Biogas Plant

The slurry is placed in an airtight digester, where bacteria decompose the organic matter over 15-40 days.

The process takes place in four stages:

- Hydrolysis – Breakdown of complex organic compounds into simple molecules.

- Acidogenesis – Formation of volatile fatty acids, alcohols, and gases.

- Acetogenesis – Conversion of acids into acetic acid, hydrogen, and CO₂.

- Methanogenesis – Methanogenic bacteria convert acetic acid and hydrogen into methane (CH₄) and carbon dioxide (CO₂).

During the biogas production process, a biogas analyzer is needed to monitor the composition of the biogas. For example, the OLGA2000 biogas online monitoring system uses advanced photoelectric sensing principles to detect and analyze methane (CH4), oxygen (O2), carbon dioxide (CO2), hydrogen sulfide (H2S) and other gases.

OLGA2000 biogas online monitoring system

3. Collection and Storage of Gobar Gas

The produced biogas is collected in a gas storage chamber and distributed through pipes to be used in homes, farms, or industries.

4. Utilization of By-Products

The leftover digestate (solid residue) is used as a nutrient-rich organic fertilizer, improving soil health and crop productivity.

Benefits of Gobar Gas Methane

1. Renewable and Sustainable

Unlike fossil fuels, gobar gas is produced from organic waste, making it renewable and self-sustaining.

2. Reduces Greenhouse Gas Emissions

Methane is a potent greenhouse gas, and capturing it for energy use prevents its release into the atmosphere.

Using gobar gas instead of firewood reduces deforestation, preserving natural ecosystems.

3. Cost-Effective for Rural Communities

Once a gobar gas plant is installed, fuel costs are almost zero, making it highly economical for rural households and farmers.

4. Efficient Waste Management

Converts cow dung, animal manure, and food waste into energy, reducing pollution and improving sanitation.

5. Produces Organic Fertilizer

The by-product of gobar gas production is a nutrient-rich fertilizer that enhances soil fertility and boosts agricultural productivity.

6. Energy Security and Independence

Reduces reliance on imported fossil fuels like LPG and diesel.

Promotes decentralized energy production, reducing transmission losses.

Modern Applications of Gobar Gas Methane

While traditionally used for cooking and heating, modern advancements have expanded the applications of gobar gas methane to various sectors:

1. Cooking and Household Use

Gobar gas is widely used in rural homes as a clean and smokeless cooking fuel, reducing health risks from indoor air pollution.

2. Electricity Generation

Biogas-powered generators convert methane into electricity, providing off-grid power to farms, villages, and small industries.

3. Compressed Biogas (CBG) for Vehicles

When purified, gobar gas can be compressed into biomethane (CBG) and used as an alternative fuel for vehicles.

India, Sweden, and Germany are promoting bio-CNG stations for public transport.

4. Industrial and Commercial Applications

Factories and dairy farms use gobar gas in boilers and heating systems to reduce dependency on fossil fuels.

Biogas is increasingly used in combined heat and power (CHP) systems to generate both electricity and heat simultaneously.

5. Integration with Solar and Wind Power

Hybrid renewable energy systems combine gobar gas with solar and wind power to ensure a continuous energy supply.

Conclusion

Gobar gas methane is a powerful traditional fuel with modern applications in cooking, electricity generation, transportation, and industry. As technology continues to improve biogas efficiency and scalability, gobar gas has the potential to be a major player in global renewable energy solutions.