As the world seeks sustainable energy solutions, converting biogas to compressed natural gas (CNG) is emerging as a key innovation. This transformative process upgrades raw biogas into a cleaner, high-energy fuel suitable for vehicles, heating, and power generation. By reducing dependence on fossil fuels and utilizing organic waste, biogas to CNG conversion offers significant environmental and economic benefits.

What is CNG and Why Convert Biogas?

Compressed natural gas (CNG) is a high-energy, low-emission fuel primarily composed of methane (CH₄). While biogas is naturally rich in methane, it also contains impurities like carbon dioxide (CO₂), water vapor, hydrogen sulfide (H₂S), and other trace gases. These impurities limit biogas’ usability as a fuel.

Converting biogas to CNG involves purifying it to meet the quality standards of natural gas, making it suitable for a wide range of applications while reducing emissions and enhancing energy efficiency.

The Biogas-to-CNG Conversion Process

1. Biogas Production:

Feedstock: Organic materials such as agricultural waste, animal manure, and food scraps are fed into an anaerobic digester.

Anaerobic Digestion: Microorganisms break down the organic matter in the absence of oxygen, producing raw biogas, which typically contains 50–65% methane.

2. Pre-Treatment:

Moisture Removal: Raw biogas often contains water vapor, which is removed using condensation or drying units.

Removal of Particulates: Filters or scrubbers are used to eliminate particulates and debris.

3. Desulfurization:

Hydrogen Sulfide Removal: H₂S, a corrosive and toxic gas, is extracted using chemical scrubbers, activated carbon filters, or biological methods.

4. Carbon Dioxide Removal:

Techniques such as pressure swing adsorption (PSA), membrane separation, or water scrubbing are employed to separate CO₂ from the biogas, increasing the methane concentration to over 90%.

5. Compression:

The purified biogas (biomethane) is compressed to high pressures (200–250 bar) to create CNG, enabling its use in vehicles and storage.

6. Storage and Distribution:

The CNG is stored in specialized tanks and distributed through pipelines, cylinder networks, or fueling stations.

7. Gas Monitoring

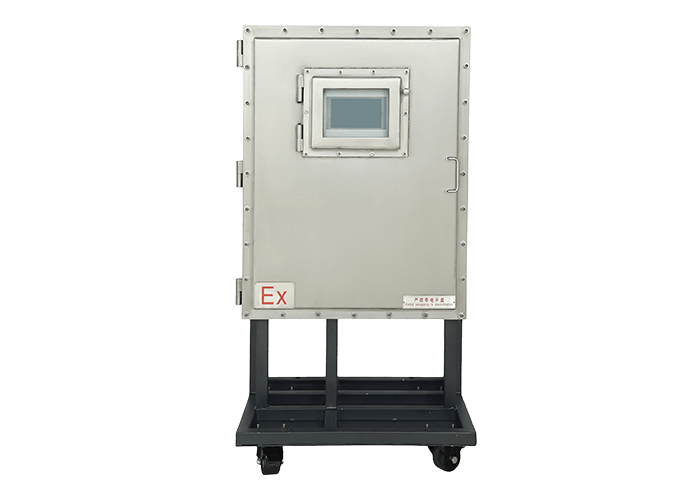

Biogas analyzer, which uses advanced photoelectric sensing principles to detect methane (CH4), oxygen (O2), carbon dioxide (CO2), hydrogen sulfide (H2S), etc. For example, the OLGA2000 biogas online monitoring system can be widely used in gas monitoring in landfill biogas power plants, petrochemical industries, coal mines and other scenarios, and can achieve remote data transmission.

biogas online monitoring system OLGA2000

Applications of Biogas-Derived CNG

1. Transportation Fuel: CNG-powered vehicles produce fewer emissions than gasoline or diesel engines, making them an eco-friendly alternative.

2. Industrial Use: Industries can use CNG for heating, power generation, and running machinery.

3. Cooking and Heating: CNG is a clean fuel option for households and commercial kitchens.

Benefits of Biogas-to-CNG Conversion

1. Renewable Energy Source: It utilizes organic waste, ensuring a sustainable and continuous energy supply.

2. Reduction in Greenhouse Gas Emissions: The process prevents methane emissions from organic waste and provides a low-carbon alternative to fossil fuels.

3. Waste Management: It offers a productive use for agricultural and food waste, reducing landfill dependency.

4. Energy Independence: Local CNG production can reduce reliance on imported natural gas.

5. Economic Opportunities: Creating biogas-to-CNG infrastructure generates jobs and supports local economies.

Challenges and Solutions

1. High Initial Costs: Setting up biogas purification and compression systems requires significant investment. Solution: Government subsidies, tax incentives, and public-private partnerships can help reduce costs.

2. Technical Expertise: Efficient operation requires skilled technicians. Solution: Training programs and accessible technology can address this gap.

3. Storage and Distribution: Limited infrastructure for CNG storage and transportation can be a bottleneck. Solution: Developing localized fueling stations and storage networks can enhance accessibility.

Future Prospects

The biogas-to-CNG conversion industry is poised for growth, driven by advancements in purification technologies and supportive government policies. Countries worldwide are investing in biogas upgrading facilities to promote CNG as a clean energy alternative for transportation and power generation.

Moreover, integrating renewable energy sources such as solar and wind with biogas systems can create hybrid models, further enhancing energy efficiency and sustainability.

Conclusion

Biogas-to-CNG conversion is a game-changer in the renewable energy sector. It bridges the gap between waste management and clean energy production, offering a practical, scalable, and eco-friendly solution to global energy challenges.