In a world facing mounting environmental challenges and an urgent need for renewable energy sources, biogas production from sewage is emerging as a promising solution. By converting waste into usable energy, biogas from sewage not only addresses waste management concerns but also provides a sustainable and clean energy alternative.

What is Biogas?

Biogas is a renewable energy source primarily composed of methane (CH₄) and carbon dioxide (CO₂), along with small amounts of other gases. It is produced through the anaerobic digestion (a process in which microorganisms break down organic matter in the absence of oxygen) of organic waste, such as food scraps, agricultural waste, and sewage. This gas is combustible, making it suitable for various energy applications, including cooking, heating, electricity generation, and even as a fuel for vehicles.

How Biogas is Produced from Sewage

The production of biogas from sewage involves multiple steps that convert wastewater and sludge into clean, renewable energy. Below is a breakdown of the key stages in this process:

1. Collection of Sewage

The biogas production process begins with the collection of sewage from residential, commercial, and industrial sources. Sewage is the wastewater and waste matter that is collected through a network of sewage pipes and transported to a treatment facility. This waste typically includes a combination of water, organic material, and microorganisms.

2. Primary Treatment

Once the sewage reaches the treatment facility, it undergoes primary treatment. In this stage, large particles and solids are removed from the wastewater through sedimentation, where heavy solids settle at the bottom of a tank and are separated. The solid sludge that is separated is what will later undergo anaerobic digestion to produce biogas.

3. Anaerobic Digestion

The sludge from primary treatment is sent to an anaerobic digester, where the actual biogas production takes place. Anaerobic digesters are large, sealed tanks that maintain an oxygen-free environment ideal for microbial activity. Here, anaerobic bacteria (microorganisms that thrive in the absence of oxygen) break down the organic matter in the sludge, producing methane, carbon dioxide, and trace gases.

The anaerobic digestion process involves four main stages:

- Hydrolysis: Complex organic materials, like proteins and carbohydrates, are broken down into simpler compounds such as amino acids and sugars.

- Acidogenesis: The simpler compounds are further broken down by bacteria, producing volatile fatty acids, hydrogen, and carbon dioxide.

- Acetogenesis: The volatile fatty acids are converted into acetic acid, hydrogen, and carbon dioxide.

- Methanogenesis: Finally, methanogenic bacteria convert acetic acid and hydrogen into methane and carbon dioxide, forming the biogas.

The process can take several days to weeks, depending on the digester’s size, temperature, and the organic content of the sludge. Optimal temperatures are usually maintained to speed up microbial activity, resulting in a steady production of biogas.

4. Biogas Collection

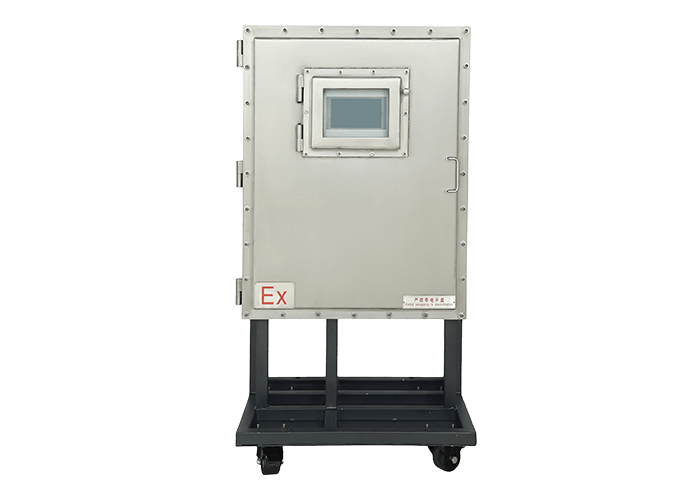

Once the biogas is produced, it rises to the top of the digester tank and is collected. This raw biogas typically consists of 50-70% methane, 30-50% carbon dioxide, and small amounts of other gases such as hydrogen sulfide (H₂S) and water vapor. During the biogas production process, a biogas analyzer is needed to monitor the composition of the biogas. For example, the OLGA2000 biogas online monitoring system uses advanced photoelectric sensing principles to detect and analyze methane (CH4), oxygen (O2), carbon dioxide (CO2), hydrogen sulfide (H2S) and other gases.

biogas online monitoring system OLGA2000

5. Biogas Purification

To make biogas suitable for practical applications, it needs to be purified to remove impurities like carbon dioxide, hydrogen sulfide, and water vapor. This purification process, known as biogas upgrading, improves the methane content, making the gas more efficient for combustion. Upgraded biogas with higher methane content (often called biomethane) can be used directly as fuel or injected into the natural gas grid.

6. Energy Utilization

After purification, biogas can be used in a variety of ways, depending on the needs of the community or facility:

- Electricity Generation: Biogas can be used to power generators and produce electricity for local communities, sewage treatment plants, or commercial applications.

- Heating: Biogas can be burned to produce heat, which can be used for industrial processes or domestic heating.

- Transportation Fuel: Upgraded biogas (biomethane) can be compressed and used as a fuel for vehicles, similar to compressed natural gas (CNG).

- Cooking and Lighting: In areas where biogas is produced at a smaller scale, it can be used directly as a clean fuel for cooking and lighting.

Environmental and Economic Benefits of Biogas from Sewage

The production of biogas from sewage brings numerous environmental and economic advantages, which make it a compelling alternative in the quest for sustainable energy.

1. Waste Reduction and Management

One of the primary benefits of biogas production from sewage is effective waste management. Sewage and sludge are considered waste materials and pose a threat to the environment if left untreated. By converting sewage into biogas, waste treatment facilities can manage waste more sustainably, reducing the need for landfill space and decreasing the risk of water contamination.

2. Reduction in Greenhouse Gas Emissions

Sewage that is left untreated releases large amounts of methane, a potent greenhouse gas, into the atmosphere. By capturing methane through anaerobic digestion and using it as fuel, biogas production from sewage reduces greenhouse gas emissions significantly. This helps combat climate change by mitigating methane’s impact on global warming.

3. Energy Independence and Cost Savings

Producing biogas from sewage provides a renewable energy source that can reduce reliance on fossil fuels. For wastewater treatment plants, this process creates an opportunity for energy self-sufficiency, as the energy generated from biogas can be used to power the plant itself, leading to significant cost savings. Some treatment plants even generate surplus energy, which can be sold back to the grid, generating revenue.

4. Production of Organic Fertilizer

The byproduct of anaerobic digestion, known as digestate, is a nutrient-rich substance that can be used as an organic fertilizer. This helps promote sustainable agriculture by providing farmers with an environmentally friendly alternative to chemical fertilizers. The use of digestate also enhances soil health and reduces soil degradation.

5. Job Creation and Economic Opportunities

Investing in biogas production infrastructure from sewage can create new jobs and stimulate local economies. From the construction of anaerobic digesters to the operation and maintenance of biogas plants, the biogas industry offers numerous employment opportunities, particularly in regions where waste management is a growing concern.

Conclusion

The production of biogas from sewage represents an innovative approach to turning waste into wealth. By leveraging the power of anaerobic digestion, we can convert harmful sewage into a valuable source of renewable energy. This process not only addresses pressing waste management issues but also contributes to energy independence, greenhouse gas reduction, and economic growth.