As the world continues to confront the environmental impacts of traditional energy sources and the growing crisis of waste management, biogas emerges as a promising solution that tackles both challenges simultaneously. Derived from organic waste, biogas turns environmental problems into a powerful renewable energy resource, helping to reduce greenhouse gas emissions, manage waste efficiently, and generate clean energy.

The Biogas Production Process

The production of biogas from organic waste involves several key steps, each contributing to the efficient conversion of waste into usable energy:

1. Collection of Organic Waste:

Organic waste is collected from various sources, including households, farms, restaurants, and wastewater treatment plants. This waste is then transported to a biogas plant where it is prepared for processing.

2. Anaerobic Digestion:

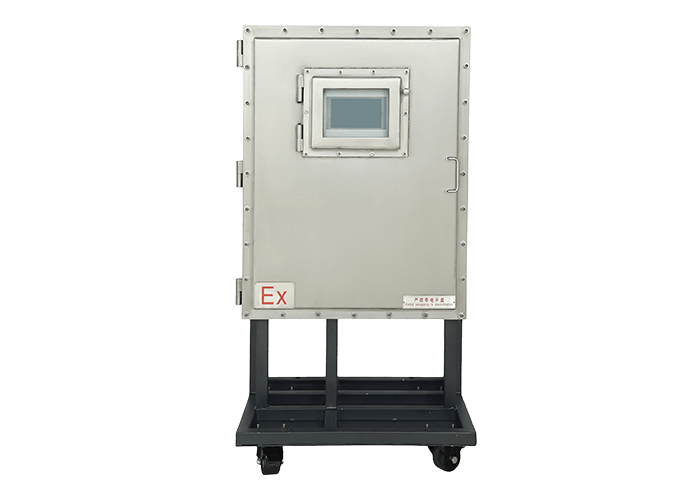

The collected waste is fed into an anaerobic digester, a sealed tank designed to create an oxygen-free environment. Here, bacteria break down the waste, producing biogas and a nutrient-rich byproduct called digestate. During the biogas production process, the required equipment is a biogas analyzer, which uses advanced photoelectric sensing principles to detect methane (CH4), oxygen (O2), carbon dioxide (CO2), hydrogen sulfide (H2S), etc. For example, the OLGA2000 biogas online monitoring system can be widely used in gas monitoring in landfill biogas power plants, petrochemicals, coal mines and other scenarios, and can achieve remote data transmission.

biogas online monitoring system OLGA2000

3. Biogas Capture and Storage:

As the waste decomposes, biogas is released and captured within the digester. This gas is then stored in a gas holder, ready for use. The biogas can be purified if necessary, removing impurities like hydrogen sulfide and water vapor to improve its quality.

4. Energy Utilization:

The captured biogas is used to generate electricity and heat, power vehicles, or even be injected into the natural gas grid after upgrading. The digestate can be used as a high-quality organic fertilizer, completing the waste-to-energy cycle.

Applications of Biogas from Organic Waste

1. Electricity Generation:

Biogas can be used in combined heat and power (CHP) units to generate electricity and heat simultaneously. This application is particularly valuable for farms, food processing plants, and wastewater treatment facilities that have a continuous supply of organic waste.

2. Cooking and Heating:

In many rural areas, biogas is used directly as a fuel for cooking and heating. This reduces the dependence on firewood, charcoal, and other traditional fuels, improving indoor air quality and reducing deforestation.

- Vehicle Fuel:

Upgraded biogas, often referred to as biomethane, can be used as a clean vehicle fuel. It offers a sustainable alternative to petrol and diesel, reducing greenhouse gas emissions from the transportation sector.

4. Grid Injection:

After purification, biogas can be injected into the natural gas grid, providing a renewable alternative to conventional natural gas. This integration helps decarbonize the gas supply, supporting the transition to a low-carbon energy system.

5. Industrial Use:

Industries that generate large amounts of organic waste, such as food and beverage manufacturers, can use biogas for their energy needs, reducing operational costs and enhancing sustainability.

Conclusion

The production of biogas from organic waste represents a transformative approach to energy and waste management. By converting everyday waste into a valuable energy resource, biogas helps reduce greenhouse gas emissions, manage waste sustainably, and provide affordable, renewable energy.