In rural areas across the globe, one of the most abundant and untapped resources is cow dung. Traditionally viewed as waste, cow dung has proven to be an invaluable resource for producing biogas, a clean, renewable source of energy. Biogas from cow dung, often referred to as gobar gas, offers a sustainable solution to many of the energy and environmental challenges faced by rural communities. By converting cow dung into biogas, rural households can generate energy for cooking, heating, and electricity, all while improving waste management, agricultural productivity, and local economies.

What is Biogas from Cow Dung?

Biogas is a mixture of methane (CH4) and carbon dioxide (CO2) produced through the anaerobic digestion of organic matter, such as cow dung, in the absence of oxygen. The process involves microorganisms that break down the dung and release methane gas, which can be captured and used as a renewable energy source.

Cow dung is an ideal feedstock for biogas production because of its high methane yield and abundance in rural areas where cattle farming is prevalent. In a typical rural household, the waste from just a few cows is enough to power biogas stoves and meet daily energy needs.

The Biogas Production Process

The process of generating biogas from cow dung involves the following steps:

- 1. Collection of Cow Dung: Cow dung is collected from animal sheds and mixed with water to form a slurry. Other organic materials, such as crop residues and kitchen waste, can also be added to the mixture to increase biogas production.

- 2. Anaerobic Digestion: The slurry is fed into an anaerobic digester, a sealed container where the organic matter breaks down in the absence of oxygen. Bacteria in the digester digest the cow dung and produce biogas, which primarily consists of methane and carbon dioxide.

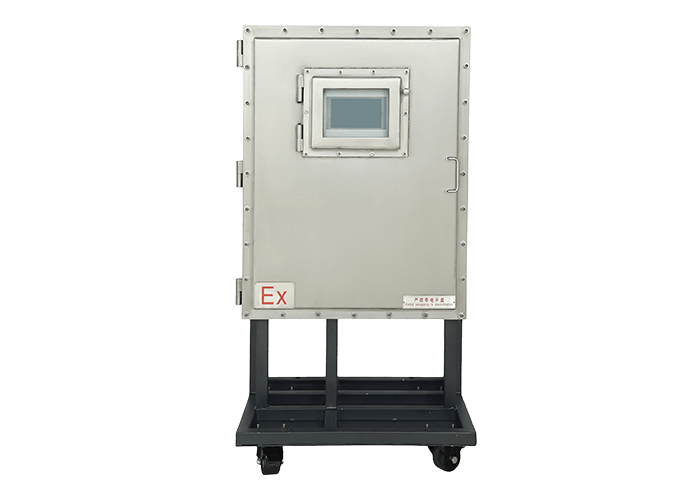

- 3. Monitoring equipment: Biogas analyzer, which uses advanced photoelectric sensing principles to detect methane (CH4), oxygen (O2), carbon dioxide (CO2), hydrogen sulfide (H2S), etc. For example, the OLGA2000 biogas online monitoring system can be widely used in gas monitoring in landfill biogas power plants, petrochemical industries, coal mines and other scenarios, and can achieve remote data transmission.

- 4. Gas Storage: The biogas rises to the top of the digester and is captured in a storage unit or dome. The stored biogas can then be piped to stoves, burners, or generators for use.

- 5. Energy Use: The methane in biogas is a combustible fuel that can be used for cooking, heating, or electricity generation.

- 6. Byproduct Use: The remaining material in the digester, known as digestate, is a nutrient-rich organic fertilizer that can be used to enrich soil and improve crop yields.

Why Biogas from Cow Dung is Ideal for Rural Areas

1. Readily Available Feedstock

One of the key advantages of using cow dung for biogas is its abundance in rural areas. In regions where livestock farming is a major livelihood, cow dung is often available in large quantities and can be collected regularly to ensure a steady supply of feedstock for biogas production.

2. Low-Cost and Sustainable Energy

For many rural households, access to electricity and cooking fuel is limited and expensive. Biogas from cow dung provides a low-cost alternative that meets daily energy needs. Once a biogas plant is installed, the energy generated is virtually free, helping households save on energy costs while reducing their reliance on firewood, kerosene, or coal.

3. Improved Health and Air Quality

One of the significant benefits of using biogas for cooking in rural areas is the reduction in indoor air pollution. Traditional cooking methods, such as burning firewood or dung cakes, release harmful smoke and pollutants that contribute to respiratory diseases. Biogas burns cleanly, producing minimal emissions, which improves indoor air quality and promotes better health, especially for women and children who spend the most time in the kitchen.

4. Better Waste Management

Cow dung, if left unmanaged, can lead to environmental pollution and the spread of diseases. Biogas plants offer a way to manage animal waste efficiently by converting it into a valuable resource—biogas. This not only reduces the environmental burden of waste but also minimizes methane emissions from decomposing dung, helping combat climate change.

5. Organic Fertilizer for Agriculture

The byproduct of the biogas production process, known as digestate, is an organic fertilizer rich in nutrients like nitrogen, phosphorus, and potassium. This digestate can be used to fertilize crops and improve soil health, reducing the need for chemical fertilizers and supporting sustainable agriculture.

Challenges and Solutions

Despite the numerous benefits of biogas from cow dung, there are challenges that rural areas may face when adopting this technology:

- Initial Investment Costs: Installing a biogas plant requires an upfront investment that may be difficult for low-income households. Governments and NGOs can offer subsidies or low-interest loans to make biogas systems more accessible.

- Technical Knowledge: Operating and maintaining a biogas plant requires some technical skills. Training programs and community workshops can be organized to educate rural residents on the proper operation of biogas systems, ensuring long-term success.

- Feedstock Supply: While cow dung is often abundant, consistent biogas production requires a steady supply of feedstock. In areas with fewer livestock, households can combine kitchen scraps and crop residues with cow dung to maintain biogas production.

Biogas from cow dung represents a powerful tool for sustainable rural development. By harnessing the energy potential of an abundant waste resource, rural communities can access clean, affordable, and renewable energy while promoting environmental conservation and improving agricultural productivity.