As the world continues to shift towards more sustainable energy solutions, biodigesters have emerged as a critical technology for converting organic waste into renewable energy. Biodigesters not only help manage waste but also produce biogas, which can be used for cooking, heating, and electricity generation. However, understanding the costs associated with installing and operating a biodigester is crucial for anyone considering investing in this sustainable technology. This article breaks down the key cost components of biodigesters and explores their financial viability.

Initial Investment Costs

1. Capital Costs:

The primary expense in setting up a biodigester is the capital cost, which includes the cost of the digester itself and related infrastructure. This involves:

– Digester Construction: The cost of materials and labor for building the digester tank, which can vary depending on the size and type of the biodigester (e.g., fixed-dome, floating-drum, or bag digester).

– Feedstock Storage and Processing Equipment: Facilities and equipment needed to store and process the organic waste before it enters the digester.

– Gas Storage and Utilization Systems: Tanks and pipelines for storing and transporting the biogas produced, along with appliances or generators to utilize the gas.

2. Site Preparation:

Preparing the site for the biodigester involves costs such as land acquisition, site clearing, and infrastructure setup (e.g., access roads and utility connections).

3. Permitting and Licensing:

Obtaining the necessary permits and licenses for installing and operating a biodigester can also incur costs. These may include environmental impact assessments, construction permits, and operational licenses.

Operational and Maintenance Costs

1. Feedstock Costs:

The cost of the organic waste (feedstock) used in the biodigester is a significant operational expense. Depending on the source, feedstock may be purchased, transported, or processed, adding to the overall cost.

2. Labor Costs:

Operating a biodigester requires skilled labor for daily operations, maintenance, and monitoring. Salaries for personnel can vary depending on the location and scale of the biodigester.

3. Maintenance and Repairs:

Regular maintenance is essential to ensure the efficient operation of the biodigester. This includes routine checks, repairs, and replacement of worn-out components, which can add to the operational costs.

4. Utilities:

The biodigester may require water, electricity, and other utilities for its operation, contributing to the ongoing expenses.

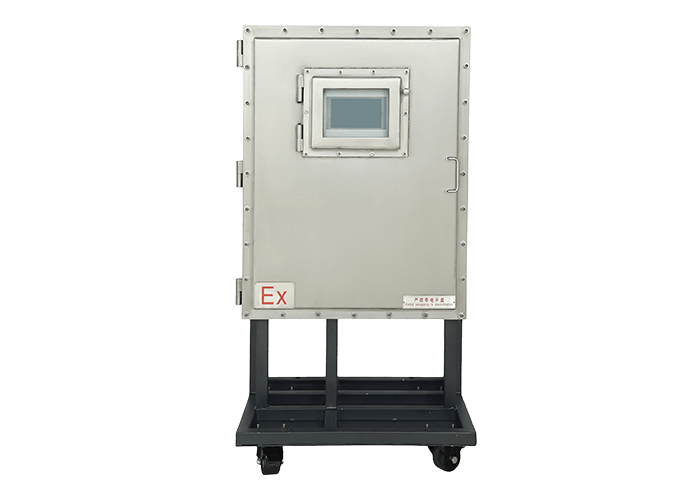

- Monitoring equipment: Biogas analyzer, which uses advanced photoelectric sensing principles to detect methane (CH4), oxygen (O2), carbon dioxide (CO2), hydrogen sulfide (H2S), etc. For example, the OLGA2000 biogas online monitoring system can be widely used in gas monitoring in landfill biogas power plants, petrochemical industries, coal mines and other scenarios, and can achieve remote data transmission.

Revenue Streams and Financial Returns

1. Biogas Production:

The primary revenue stream from a biodigester is the biogas produced, which can be used for cooking, heating, or electricity generation. The value of the biogas depends on local energy prices and the scale of production.

2. Digestate Sales:

The byproduct of the anaerobic digestion process, known as digestate, is a nutrient-rich fertilizer that can be sold to generate additional income. The market for organic fertilizers is growing, providing a lucrative opportunity for biodigester owners.

3. Renewable Energy Credits (RECs):

In some regions, producing renewable energy entitles biodigester operators to earn RECs, which can be sold to utilities or other entities to meet renewable energy compliance targets.

4. Carbon Credits:

By reducing methane emissions from organic waste decomposition, biodigesters contribute to lowering greenhouse gas emissions. This reduction can be monetized through carbon credits, which can be traded in carbon markets.

Conclusion

Investing in a biodigester involves significant initial and ongoing costs, but the potential returns in terms of biogas production, digestate sales, and environmental benefits make it a promising sustainable energy solution. By carefully analyzing the capital and operational costs, potential revenue streams, and conducting a thorough cost-benefit analysis, investors can make informed decisions about the financial viability of biodigester projects.