As the world grapples with the dual challenges of energy security and environmental sustainability, biogas power plants have emerged as a vital part of the renewable energy landscape. By converting organic waste into clean, renewable energy, these plants offer a sustainable solution to reduce greenhouse gas emissions and manage waste more efficiently.

What is Biogas?

Biogas is a type of biofuel that is naturally produced from the decomposition of organic waste in an oxygen-free (anaerobic) environment. It primarily consists of methane (CH₄) and carbon dioxide (CO₂), along with small amounts of hydrogen sulfide (H₂S) and moisture. Common sources of biogas include agricultural waste, food waste, animal manure, sewage sludge, and organic industrial waste.

The Biogas Production Process

1. Feedstock Collection:

– Organic waste materials are collected and stored before being fed into the anaerobic digester. The type of feedstock can vary widely, including agricultural residues, food scraps, and animal manure.

2. Anaerobic Digestion:

- The organic waste is placed into the anaerobic digester, a sealed, oxygen-free container. Here, microorganisms break down the waste through a series of processes:

- Hydrolysis: Complex organic molecules are broken down into simpler molecules like sugars, amino acids, and fatty acids.

- Acidogenesis: The simpler molecules are converted into volatile fatty acids, alcohols, hydrogen, and carbon dioxide.

- Acetogenesis: The volatile fatty acids and alcohols are further broken down into acetic acid, hydrogen, and carbon dioxide.

- Methanogenesis: Methanogenic bacteria convert the acetic acid, hydrogen, and carbon dioxide into methane and carbon dioxide, producing biogas.

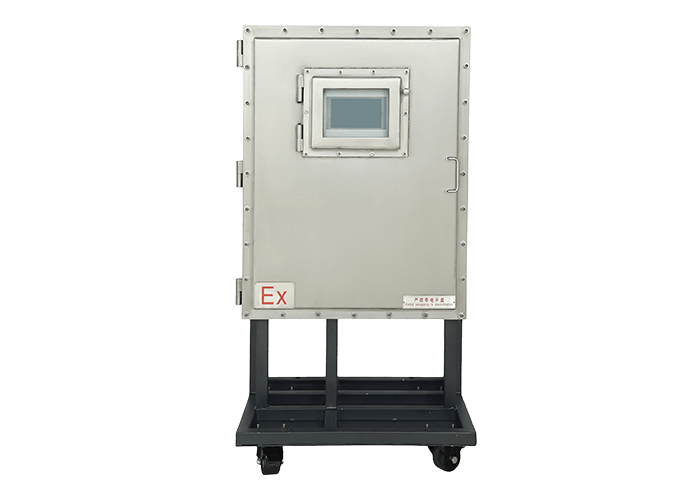

- Monitoring equipment: During the biogas production process, the required equipment is a biogas analyzer, which uses advanced photoelectric sensing principles to detect methane (CH4), oxygen (O2), carbon dioxide (CO2), hydrogen sulfide (H2S), etc. For example, the OLGA2000 biogas online monitoring system can be widely used in gas monitoring in landfill biogas power plants, petrochemicals, coal mines and other scenarios, and can achieve remote data transmission.

3. Biogas Collection:

The biogas produced is collected in a gas holder or storage tank, ready for further processing or direct use.

Converting Biogas to Electricity

1. Gas Cleaning and Conditioning:

– Raw biogas contains impurities like hydrogen sulfide, moisture, and particulates that need to be removed to prevent damage to equipment and ensure efficient combustion. Gas cleaning systems scrub and condition the biogas to meet the required standards for power generation.

2. Biogas Engine or Turbine:

– The cleaned biogas is fed into a biogas engine or turbine. These engines are specifically designed to run on biogas, utilizing the methane content for combustion. The combustion process drives the engine or turbine, generating mechanical energy.

3. Electricity Generation:

– The mechanical energy produced by the biogas engine or turbine is converted into electrical energy using an alternator or generator. The generated electricity can then be fed into the grid or used on-site.

4. Heat Recovery:

– Biogas power plants often employ combined heat and power (CHP) systems, which capture the waste heat produced during electricity generation. This heat can be used for various applications, such as heating buildings, drying agricultural products, or powering additional industrial processes, thereby improving overall efficiency.

Key Components of a Biogas Power Plant

- Anaerobic Digester: The core unit where anaerobic digestion occurs, breaking down organic waste to produce biogas.

- Gas Storage: Tanks or gas holders that store the produced biogas before it is cleaned and conditioned.

- Gas Cleaning System: Equipment that removes impurities from the biogas to make it suitable for combustion.

- Biogas Engine or Turbine: Engines or turbines designed to combust biogas and generate mechanical energy.

- Generator: Converts mechanical energy into electrical energy.

- Heat Recovery System: Captures and utilizes waste heat from the power generation process.

Benefits of Biogas Power Plants

1. Renewable Energy Source:

– Biogas is a renewable energy source, reducing reliance on fossil fuels and contributing to energy security.

2. Waste Management:

– Biogas power plants help manage organic waste efficiently, reducing the amount of waste sent to landfills and minimizing methane emissions from decomposing waste.

3. Greenhouse Gas Reduction:

– By capturing and utilizing methane, a potent greenhouse gas, biogas power plants help mitigate climate change.

4. Energy Efficiency:

– Combined heat and power systems improve overall energy efficiency by utilizing waste heat for additional applications.

5. Economic Benefits:

Biogas power plants create economic opportunities, particularly in rural areas, by providing renewable energy, reducing waste disposal costs, and generating revenue from electricity and heat sales.

Biogas power plants offer a sustainable and efficient way to convert organic waste into renewable energy, addressing both waste management and energy production challenges. By understanding how these plants work and the benefits they provide, we can better appreciate their role in creating a cleaner, greener future. As technology advances and adoption increases, biogas power plants will continue to play a crucial part in the global transition to sustainable energy sources.