As the world strives for sustainable and eco-friendly alternatives to fossil fuels, biogas compressed natural gas (CNG) plants emerge as a transformative solution for the transportation sector. Biogas CNG offers a renewable and cleaner fuel option, reducing greenhouse gas emissions and dependence on conventional fossil fuels. This article explores the potential of biogas CNG plants in shaping the future of transportation.

What is Biogas CNG?

Biogas is produced through the anaerobic digestion of organic materials such as agricultural waste, manure, municipal waste, plant material, sewage, green waste, or food waste. The resulting biogas, primarily composed of methane (CH₄) and carbon dioxide (CO₂), can be purified to remove impurities and then compressed to produce compressed natural gas (CNG).

Biogas CNG, therefore, refers to biogas that has been purified and compressed to be used as a fuel in CNG-powered vehicles. This process not only provides a renewable energy source but also utilizes waste materials that would otherwise contribute to environmental pollution.

The Production Process

1. Anaerobic Digestion

Organic waste materials are collected and fed into an anaerobic digester, where they are broken down by microorganisms in the absence of oxygen. This process produces biogas, which consists mainly of methane and carbon dioxide.

2. Biogas Purification

Raw biogas contains impurities such as hydrogen sulfide (H₂S), moisture, and siloxanes. These impurities must be removed to produce a high-quality fuel. The purification process typically involves:

- Desulfurization: Removing hydrogen sulfide.

- Dehydration: Removing water vapor.

- Carbon Dioxide Removal: Reducing the carbon dioxide content to increase methane concentration.

- Siloxane Removal: Eliminating siloxanes that can damage engines.

3. Compression

Once purified, the biogas is compressed to high pressures (typically around 200-250 bar) to produce CNG. This compressed biogas is then stored in high-pressure cylinders for use as a vehicle fuel.

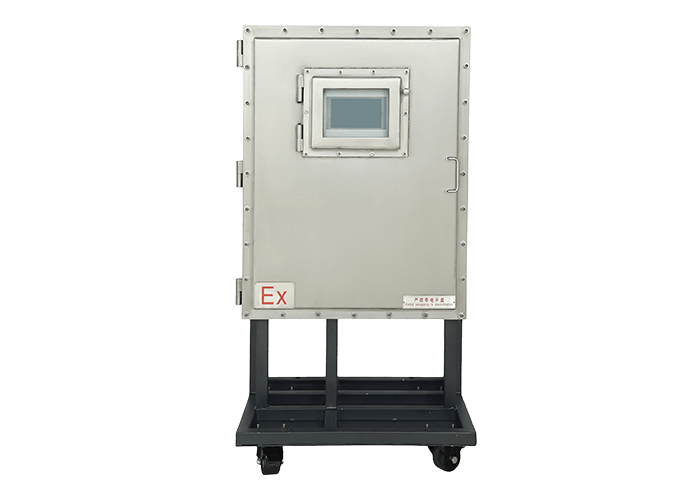

4. Gas monitoring

During the biogas production process, the required equipment is a biogas analyzer, which uses advanced photoelectric sensing principles to detect and analyze methane (CH4), oxygen (O2), carbon dioxide (CO2), hydrogen sulfide (H2S) and other gases. For example OLGA2000 Online Biogas Monitoring System can be widely used in gas monitoring in landfill gas power plants, petrochemicals, coal mines and other scenarios, and can realize remote data transmission.

Advantages of Biogas CNG in Transportation

1. Environmental Benefits

– Reduced Emissions: Biogas CNG produces significantly lower emissions of carbon dioxide, nitrogen oxides (NOx), and particulate matter compared to diesel and gasoline. This contributes to improved air quality and reduced greenhouse gas emissions.

– Waste Utilization: Using organic waste to produce biogas CNG helps in waste management, reducing landfill use and methane emissions from decomposing waste.

2. Renewable and Sustainable

Biogas CNG is a renewable energy source that can be continuously produced from organic waste. Unlike fossil fuels, which are finite and depleting, biogas CNG offers a sustainable solution for long-term energy needs.

3. Energy Security

By producing biogas CNG locally, countries can reduce their dependence on imported fossil fuels, enhancing energy security and stability. This is particularly important for regions with limited access to conventional energy sources.

4. Economic Opportunities

The biogas CNG industry creates economic opportunities through job creation in plant construction, operation, and maintenance. It also supports local economies by generating revenue from waste management and energy production.

Future Prospects

1. Integration with Circular Economy

Biogas CNG aligns with the principles of a circular economy by turning waste into a valuable resource. This integration supports sustainable development and resource efficiency.

2. Policy Support and Incentives

Governments around the world are recognizing the potential of biogas CNG and implementing policies and incentives to promote its adoption. This includes subsidies, tax incentives, and regulatory frameworks that encourage investment in biogas infrastructure.

3. Technological Innovations

Ongoing research and development in biogas production and purification technologies are driving innovations that improve efficiency, reduce costs, and enhance the scalability of biogas CNG plants.

4. Expansion of Biogas CNG Fleets

As infrastructure develops and awareness grows, more public and private fleets are expected to transition to biogas CNG vehicles. This includes public transportation, waste collection trucks, and delivery fleets, further reducing the carbon footprint of transportation.

Conclusion

Biogas CNG plants offer a transformative solution for the future of transportation, providing a renewable, sustainable, and environmentally friendly alternative to conventional fossil fuels. By harnessing the power of organic waste, biogas CNG not only addresses waste management challenges but also contributes to energy security and greenhouse gas reduction.