Biogas upgrading is a critical process that transforms raw biogas into high-purity biomethane, making it suitable for injection into the natural gas grid or use as a vehicle fuel. While biogas itself is a valuable renewable energy source, upgrading it adds significant value by enhancing its purity and usability. However, the process involves various costs that must be understood to ensure financial viability. This article explores the key cost factors involved in biogas upgrading and what you need to know to optimize your investment.

1. Initial Capital Investment

a. Upgrading Technology:

The choice of upgrading technology significantly impacts the initial capital expenditure. Common technologies include pressure swing adsorption (PSA), membrane separation, water scrubbing, and chemical scrubbing. Each technology has different capital requirements, efficiency rates, and operational complexities.

b. Infrastructure Development:

Constructing the necessary infrastructure, such as pipelines, storage tanks, and gas purification units, contributes to the capital costs. The extent and scale of infrastructure depend on the volume of biogas being processed and the desired purity level of the biomethane.

2. Operational Costs

a. Energy Consumption:

Biogas upgrading processes consume energy, which adds to the operational costs. For instance, PSA and membrane separation require electricity to compress and purify the gas, while water and chemical scrubbing require energy for pumps and heaters.

b. Consumables:

Certain upgrading technologies, such as chemical scrubbing, involve consumables like solvents and chemicals that need regular replenishment. These consumables add to the ongoing operational expenses.

c. Maintenance and Repairs:

Regular maintenance of upgrading equipment is essential to ensure optimal performance and longevity. This includes routine inspections, part replacements, and unforeseen repairs, all of which contribute to operational costs.

3. Feedstock Quality and Pre-treatment

a. Feedstock Variability:

The quality and composition of the raw biogas feedstock can vary depending on its source (e.g., agricultural waste, landfill gas, or wastewater treatment plant effluent). Higher levels of impurities such as hydrogen sulfide, moisture, and siloxanes require more intensive upgrading processes, increasing costs.

b. Pre-treatment Requirements:

To protect upgrading equipment and improve efficiency, raw biogas often requires pre-treatment to remove contaminants. Pre-treatment steps such as desulfurization, dehumidification, and particulate removal add to the overall cost.

4. Regulatory Compliance

a. Permitting and Licensing:

Obtaining the necessary permits and licenses for operating a biogas upgrading facility involves costs. Compliance with local, regional, and national regulations, as well as meeting safety and environmental standards, is mandatory and can be expensive.

b. Monitoring and Reporting:

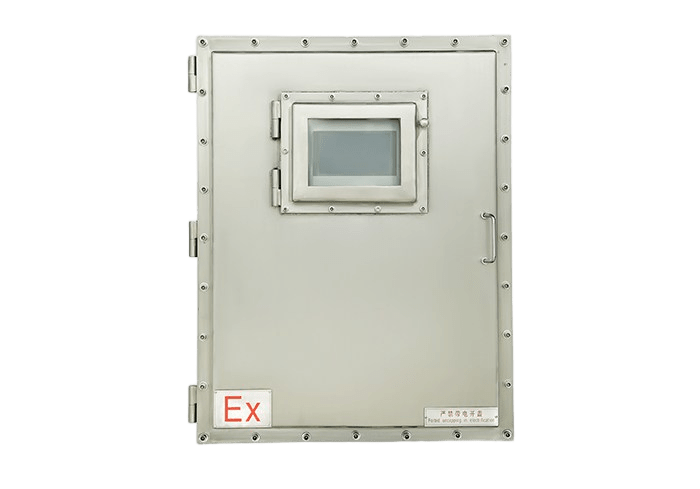

Regular monitoring and reporting are required to ensure compliance with regulatory standards. This includes emissions testing, quality control, and periodic audits, all of which add to operational expenses. For example, the OLGA2000 biogas online monitoring system uses advanced photoelectric sensing principles to detect and analyze methane (CH4), oxygen (O2), carbon dioxide (CO2), hydrogen sulfide (H2S) and other gases.

5. Revenue Generation and Financial Incentives

a. Biomethane Sales:

The primary revenue stream from biogas upgrading is the sale of high-purity biomethane. The market price for biomethane depends on its intended use (e.g., grid injection, vehicle fuel) and prevailing market conditions.

b. Renewable Energy Credits (RECs):

Biomethane production may qualify for renewable energy credits or certificates, which can be sold to utilities or other entities to meet renewable energy targets. These credits provide an additional revenue stream.

c. Government Subsidies and Incentives:

Many governments offer financial incentives, subsidies, or grants for renewable energy projects, including biogas upgrading. These incentives can significantly offset the initial capital investment and ongoing operational costs.

Conclusion

Understanding the cost factors involved in biogas upgrading is crucial for making informed investment decisions and optimizing financial returns. From initial capital investments in technology and infrastructure to ongoing operational expenses and regulatory compliance, each cost component plays a vital role in the overall economic viability of a biogas upgrading project. By carefully analyzing these factors and exploring opportunities for cost optimization and revenue generation, stakeholders can maximize the benefits of biogas upgrading and contribute to a more sustainable energy future.