Biogas production has gained significant attention as a sustainable solution for waste management and renewable energy generation. However, maximizing the efficiency and output of biogas plants is crucial for their economic viability and environmental impact. One of the key methodologies for achieving this optimization is the Biochemical Methane Potential (BMP) approach. This article explores the BMP approach, its significance in biogas production, and how it can be utilized to optimize biogas yield.

Understanding the BMP Approach

The Biochemical Methane Potential (BMP) test is a laboratory procedure used to evaluate the maximum methane production potential of a given organic substrate under anaerobic conditions. By providing insights into the biodegradability and methane yield of various feedstocks, the BMP approach helps in selecting the most suitable substrates and optimizing the anaerobic digestion process.

Key Steps in the BMP Approach

- 1. Sample Collection and Preparation:

– The first step involves collecting representative samples of the organic substrates intended for biogas production. These can include agricultural residues, food waste, manure, and other organic materials.

– The samples are then homogenized and, if necessary, pre-treated to enhance their biodegradability. Pre-treatment methods can include mechanical, thermal, or chemical processes to break down complex organic structures.

- 2. Inoculum Selection:

– An inoculum, which is a microbial community capable of anaerobic digestion, is chosen. The inoculum is usually sourced from an active anaerobic digester to ensure it contains a diverse and active microbial population.

– The ratio of inoculum to substrate is carefully controlled to provide an optimal environment for microbial activity.

- 3. Incubation:

– The prepared samples are placed in sealed bioreactors or fermentation bottles along with the inoculum.

– These bioreactors are maintained under controlled anaerobic conditions, typically at mesophilic (30-40°C) or thermophilic (50-60°C) temperatures, to facilitate microbial activity.

- 4. Methane Measurement:

– Methane production is monitored regularly throughout the incubation period, which can last from a few days to several weeks, depending on the substrate and digestion conditions.

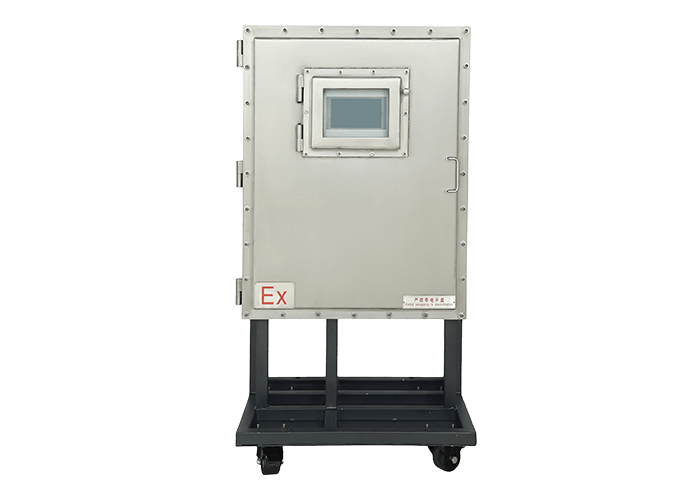

– During the biogas production process, a biogas analyzer is needed to monitor the composition of the biogas. For example, the OLGA2000 biogas online monitoring system uses advanced photoelectric sensing principles to detect and analyze methane (CH4), oxygen (O2), carbon dioxide (CO2), hydrogen sulfide (H2S) and other gases.

Benefits of the BMP Approach

- 1. Feedstock Evaluation:

– The BMP approach allows for the assessment of different feedstocks’ methane potential, enabling operators to select the most efficient and cost-effective substrates for biogas production.

– By identifying high-yield substrates, biogas plants can optimize their feedstock mix and maximize biogas output.

- 2. Process Optimization:

– BMP tests provide valuable data on the biodegradability and digestion kinetics of substrates, helping to identify potential inhibitors and optimize digestion conditions.

– Adjustments to parameters such as temperature, pH, and retention time can be made based on BMP results to enhance the overall efficiency of the anaerobic digestion process.

- 3. Economic Viability:

– By maximizing methane yield and improving process efficiency, the BMP approach contributes to the economic viability of biogas plants.

– Higher biogas production translates to increased energy generation and revenue from biogas sales, as well as potential cost savings in waste disposal.