In the quest for sustainable energy solutions, commercial biogas plants are emerging as key players, offering a versatile and environmentally friendly alternative to traditional fossil fuels. These plants utilize organic waste, such as agricultural residues, food scraps, and animal manure, to produce biogas through anaerobic digestion. As technology advances and the demand for renewable energy grows, innovations in commercial biogas plants are driving sustainability forward. In this article, we explore some of the latest advancements shaping the future of biogas production on a commercial scale.

1. Advanced Digester Technologies:

– High-Rate Anaerobic Digesters: High-rate digesters accelerate the digestion process, allowing for faster biogas production and increased throughput capacity.

– Two-Stage Digestion Systems: Two-stage digestion systems optimize biogas yield by separating the digestion process into multiple stages, each with specific conditions tailored to different types of organic waste.

– Hybrid Digestion Systems: Hybrid digestion systems combine anaerobic digestion with complementary processes, such as aerobic digestion or hydrothermal processing, to maximize resource recovery and energy output.

2. Co-Digestion and Feedstock Flexibility:

Commercial biogas plants are increasingly adopting co-digestion strategies, which involve blending multiple feedstocks to optimize biogas production. Innovations in feedstock preprocessing and digestion allow for greater flexibility in feedstock selection, enabling plants to utilize diverse organic materials, including waste streams from agriculture, food processing, and municipal sources.

3. Biogas Upgrading and Utilization:

Advancements in biogas upgrading technologies enable commercial biogas plants to produce high-purity biomethane suitable for injection into natural gas pipelines or use as vehicle fuel. Additionally, innovative gas utilization systems, such as combined heat and power (CHP) units and fuel cells, maximize the energy efficiency and revenue potential of biogas by simultaneously generating electricity and heat.

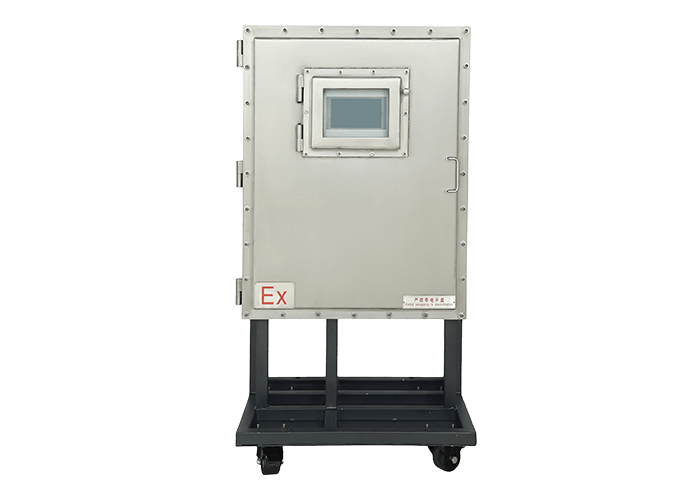

4. Automation and Monitoring Systems:

Automation and monitoring systems are revolutionizing the operation and maintenance of commercial biogas plants. Advanced sensors, remote monitoring capabilities, and data analytics tools allow plant operators to optimize process parameters, detect anomalies, and improve overall performance in real time. For example, the OLGA2000 biogas online monitoring system can be widely used in gas monitoring in landfill biogas power plants, petrochemical industries, coal mines and other scenarios, and can achieve remote data transmission.

5. Integration with Circular Economy Principles:

Commercial biogas plants are increasingly integrated with circular economy principles, where waste streams are viewed as valuable resources to be repurposed and recycled. By partnering with local businesses and industries, biogas plants can co-digest organic waste streams, recover nutrients from digestate for agricultural use, and support closed-loop resource management systems.

Conclusion:

Innovations in commercial biogas plants are driving sustainability forward by transforming organic waste into renewable energy, nutrient-rich fertilizer, and other valuable products. By embracing advanced digester technologies, co-digestion strategies, biogas upgrading systems, automation, and circular economy principles, commercial biogas plants are poised to play a pivotal role in the transition to a more sustainable and resilient energy future.