In the quest for sustainable energy solutions, gobar gas plants—also known as biogas plants—are gaining traction as a viable option, particularly in rural and agricultural settings. Derived from the anaerobic digestion of organic materials such as animal dung, these plants offer a renewable and eco-friendly source of energy. In this exploration, we delve into gobar gas plant projects, examining their significance, operation, benefits, and potential for sustainable energy generation.

Understanding Gobar Gas Plants:

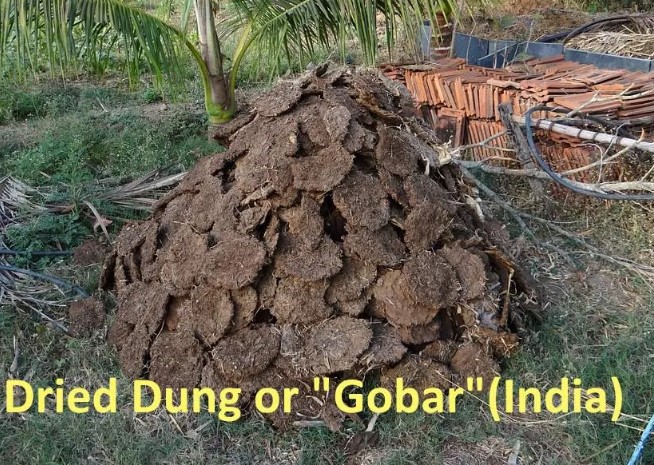

Gobar gas plants utilize the process of anaerobic digestion to convert organic waste, primarily animal dung (gobar), into biogas. Anaerobic digestion occurs in a sealed digester tank where microorganisms break down the organic matter in the absence of oxygen, producing biogas as a byproduct. This biogas, composed mainly of methane and carbon dioxide, can be utilized for cooking, heating, lighting, and even electricity generation.

Operation of Gobar Gas Plants:

Gobar gas plants typically consist of the following components:

1. Digester Tank: The heart of the gobar gas plant where anaerobic digestion takes place. The tank is usually constructed from concrete or brick and is sealed to create an oxygen-free environment.

2. Inlet for Feedstock: Animal dung, along with other organic waste such as agricultural residues or kitchen waste, is fed into the digester tank through an inlet.

3. Gas Outlet: As organic matter decomposes, biogas is produced and collected at the top of the digester tank. A gas outlet allows for the extraction and utilization of biogas.

4. Gas Storage and Distribution: Biogas is typically stored in a gas holder or storage tank before being utilized. It can be piped directly to cooking stoves, lamps, or other appliances for use.

Benefits of Gobar Gas Plant Projects:

1. Renewable Energy Generation: Gobar gas plants provide a renewable source of energy derived from organic waste, reducing dependence on fossil fuels and mitigating greenhouse gas emissions.

2. Waste Management: By utilizing animal dung and other organic waste as feedstock, gobar gas plants help manage agricultural and livestock waste, reducing pollution and odors associated with open-air dung heaps.

3. Cost Savings: Biogas produced from gobar gas plants can replace traditional cooking fuels such as firewood, charcoal, or liquefied petroleum gas (LPG), leading to significant cost savings for households and communities.

4. Improved Indoor Air Quality: Clean-burning biogas reduces indoor air pollution compared to traditional cooking methods, thereby improving health outcomes, particularly for women and children who are often exposed to smoke from biomass combustion.

Challenges and Considerations:

1. Initial Investment: While gobar gas plants offer long-term benefits, the initial investment in infrastructure and construction can be a barrier for some communities, particularly in rural areas with limited financial resources.

2. Maintenance Requirements: Regular maintenance and monitoring are essential to ensure the efficient operation of gobar gas plants. This includes periodic cleaning of the digester tank, troubleshooting gas leaks, and managing feedstock supply.

3. Feedstock Availability: The availability and quantity of animal dung and other organic waste may fluctuate seasonally, affecting biogas production rates and plant performance.

4. Technical Expertise: Proper design, construction, and operation of gobar gas plants require technical expertise and training, particularly for communities implementing these projects for the first time.

Conclusion:

Gobar gas plant projects represent a promising avenue for sustainable energy generation, waste management, and rural development. By harnessing the power of anaerobic digestion, these projects offer a renewable and eco-friendly solution to meet energy needs while addressing environmental challenges. With continued investment, innovation, and community engagement, gobar gas plants have the potential to play a significant role in the transition towards a more sustainable and resilient future.