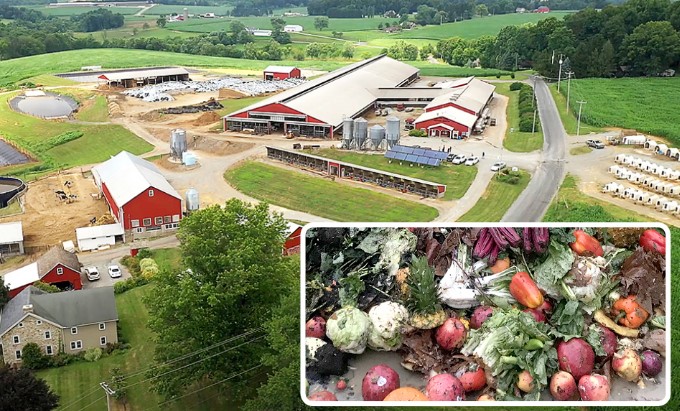

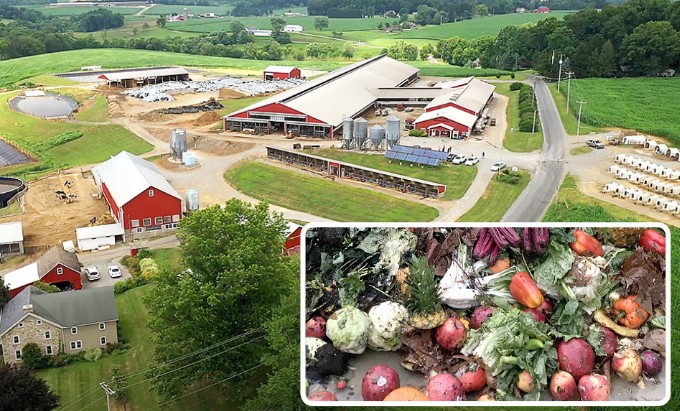

In an era where sustainable energy solutions are becoming increasingly imperative, biogas emerges as a beacon of hope in the renewable energy landscape. Derived from organic waste materials such as agricultural residues, food scraps, and animal manure, biogas production offers a promising pathway towards a cleaner and more sustainable future. Central to this process is the biogas plant, where the transformation from waste to energy takes place.

Understanding the Biogas Plant Process

- 1. Feedstock Collection: The process begins with the collection of organic waste materials, known as feedstock. This can include a variety of sources such as crop residues, animal waste, food waste from households or industries, and organic byproducts from agricultural or food processing activities.

- 2. Anaerobic Digestion: The collected feedstock is then fed into the anaerobic digester, the heart of the biogas plant. Here, microorganisms break down the organic matter in the absence of oxygen, producing biogas as a byproduct. Anaerobic digestion occurs in a controlled environment, typically within a sealed tank or chamber.

- 3. Biogas Production: Biogas, primarily composed of methane (CH4) and carbon dioxide (CO2), is generated during the anaerobic digestion process. Methane is the main component of biogas and serves as the primary source of energy. The composition of biogas can vary depending on factors such as the type of feedstock used and the operating conditions of the digester.

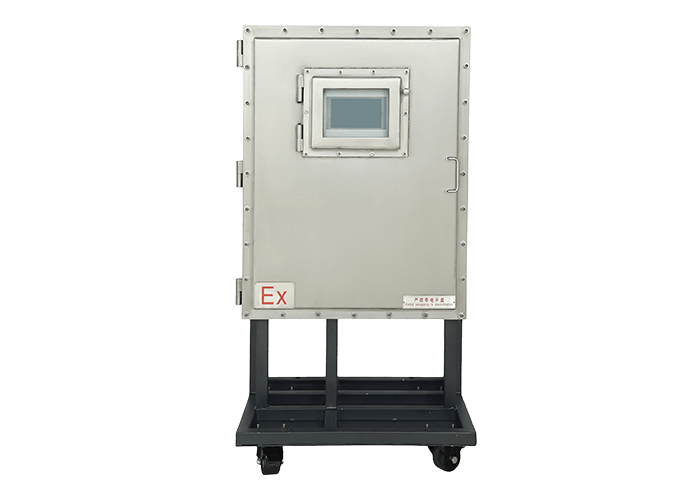

During the biogas production process, a biogas analyzer is needed to monitor the composition of the biogas. For example, the OLGA2000 biogas online monitoring system uses advanced photoelectric sensing principles to detect and analyze methane (CH4), oxygen (O2), carbon dioxide (CO2), hydrogen sulfide (H2S) and other gases.

- 4. Gas Collection and Purification: The biogas produced is then collected and purified to remove impurities such as hydrogen sulfide (H2S), moisture, and other trace gases. This purification process helps improve the quality of biogas and ensures its suitability for various applications.

- 5. Energy Utilization: The purified biogas can be utilized in a variety of ways to generate energy. Common applications include electricity generation through biogas-fired turbines or engines, as well as heat production for heating purposes in residential, commercial, or industrial settings. Biogas can also be upgraded to biomethane, a renewable natural gas suitable for injection into the natural gas grid or used as a transportation fuel.

Benefits of Biogas Plants

- 1. Renewable Energy Generation: Biogas plants harness the energy potential of organic waste materials, providing a renewable and sustainable source of energy.

- 2. Waste Management Solution: By converting organic waste into biogas, biogas plants help mitigate environmental pollution and reduce the reliance on landfills, contributing to effective waste management practices.

- 3. Greenhouse Gas Reduction: Anaerobic digestion of organic waste in biogas plants helps mitigate greenhouse gas emissions by capturing methane, a potent greenhouse gas, and converting it into energy.

- 4. Resource Recovery: Biogas production not only generates energy but also produces valuable byproducts such as digestate, a nutrient-rich organic fertilizer that can be utilized in agriculture, closing the loop on resource utilization.

Conclusion

Biogas plants represent a sustainable and environmentally friendly solution for waste management and energy generation. By efficiently converting organic waste into biogas, these plants play a vital role in the transition towards a circular economy and a greener future. Navigating the biogas plant process—from waste to energy—offers a promising pathway to reduce reliance on fossil fuels, mitigate climate change, and promote sustainable development.