Biogas, often dubbed as “green gold,” is a renewable energy source derived from the anaerobic digestion of organic materials. This natural process produces a mixture of methane, carbon dioxide, and other gases, which can be harnessed for various energy applications. Building a biogas plant involves several intricate steps, from feed-stock selection to gas utilization. In this comprehensive guide, we unveil the process of unlocking the potential of biogas plants, exploring each stage in detail.

1. Selecting the Right Feed-stock:

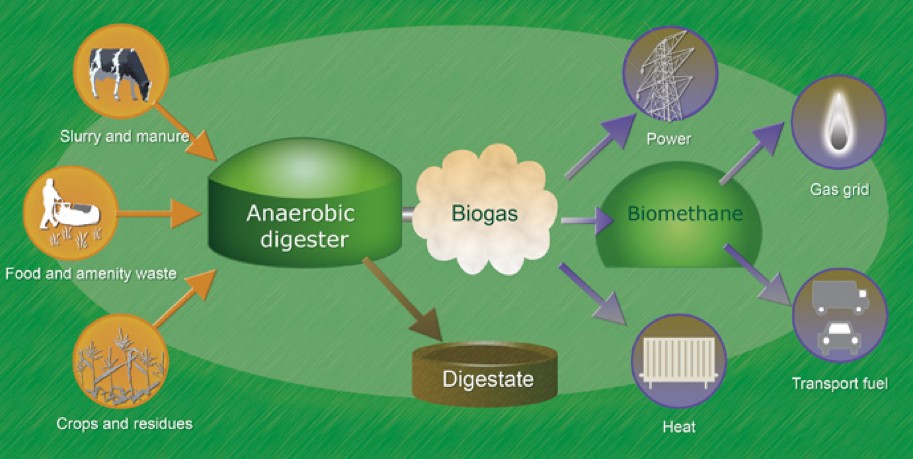

The first step in the biogas plant process is selecting suitable feed-stock. Organic materials such as agricultural residues, food waste, animal manure, and energy crops are commonly used. It’s essential to consider feed-stock availability, composition, and digestibility to optimize biogas production.

2. Anaerobic Digestion:

Anaerobic digestion is the heart of the biogas plant process. In this biological process, microorganisms break down organic matter in the absence of oxygen, producing biogas as a byproduct. The process occurs in a sealed digester tank, where temperature, pH, and moisture levels are carefully controlled to optimize microbial activity.

3. Gas Collection and Storage:

Once produced, biogas is collected from the digester tank and stored for later use. Gas storage systems, such as gas holders or gas bags, are employed to accommodate fluctuations in biogas production and demand. Proper gas storage ensures a steady supply of biogas for energy applications.

4. Gas Upgrading and Purification:

Raw biogas contains impurities such as carbon dioxide, hydrogen sulfide, and moisture, which must be removed to enhance its quality and usability.

5. Gas Utilization:

The final stage of the biogas plant process involves utilizing the purified biogas for energy generation or other applications.

6. Digestate Management:

In addition to biogas production, anaerobic digestion produces a nutrient-rich byproduct called digestate. Proper management of digestate is essential to minimize environmental impacts and maximize its agronomic value. Digestate can be used as a soil conditioner, organic fertilizer, or substrate for further composting.

7. Monitoring and Maintenance:

Continuous monitoring and maintenance are essential to ensure the efficient operation of biogas plants. Parameters such as gas production, temperature, pH, and gas composition should be regularly monitored to detect any deviations from optimal conditions. Routine maintenance tasks, such as equipment inspection, cleaning, and repair, help prevent downtime and optimize plant performance.

Biogas analyzer, which uses advanced photoelectric sensing principles to detect methane (CH4), oxygen (O2), carbon dioxide (CO2), hydrogen sulfide (H2S), etc. For example, the OLGA2000 biogas online monitoring system can be widely used in gas monitoring in landfill biogas power plants, petrochemical industries, coal mines and other scenarios, and can achieve remote data transmission.

Conclusion: Unleashing the Power of Biogas Plants

Biogas plants hold immense potential as a renewable energy solution, offering a sustainable way to manage organic waste while producing clean and versatile energy. By understanding and optimizing each stage of the biogas plant process, stakeholders can unlock the full potential of biogas as a green energy source. With proper feed-stock selection, efficient anaerobic digestion, gas upgrading, and utilization, biogas plants play a crucial role in the transition towards a more sustainable and resilient energy future.