Gobar gas, also known as biogas, offers a sustainable and eco-friendly solution for meeting energy needs while managing organic waste. Derived from the anaerobic digestion of organic materials such as animal dung, agricultural residues, and kitchen waste, gobar gas plants provide clean energy for cooking, heating, and electricity generation. Understanding the factors influencing gobar gas plant prices is essential for individuals and communities seeking to invest in renewable energy solutions. In this article, we delve into the various components that contribute to gobar gas plant prices and offer insights into what you need to know before making a purchase.

1. Plant Capacity:

The size and capacity of the gobar gas plant significantly impact its price. Larger plants capable of processing higher volumes of organic waste will generally be more expensive than smaller-scale systems designed for household use. The capacity requirement should align with the amount of organic waste available for digestion and the energy demands of the users.

2. Digester Design:

Gobar gas plants come in different designs, including fixed-dome digesters, floating-drum digesters, and plug-flow digesters, among others. Each design has its construction requirements, material specifications, and associated costs. Factors such as durability, ease of maintenance, and gas production efficiency should be considered when selecting a digester design.

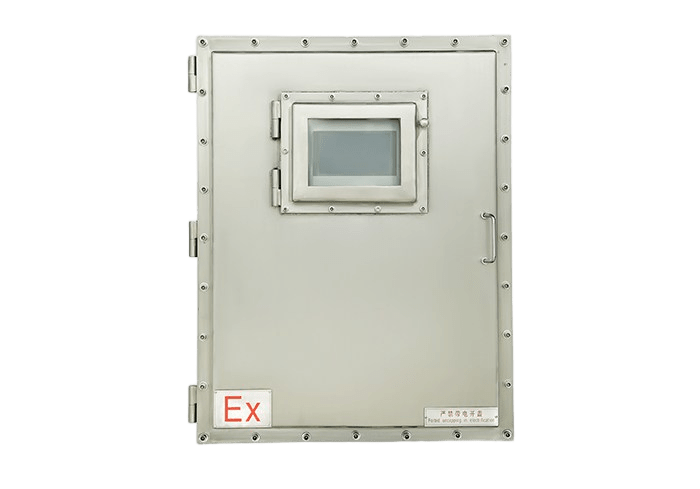

3. Monitoring equipment:

Biogas analyzer, which uses advanced photoelectric sensing principles to detect methane (CH4), oxygen (O2), carbon dioxide (CO2), hydrogen sulfide (H2S), etc. For example, the OLGA2000 biogas online monitoring system can be widely used in gas monitoring in landfill biogas power plants, petrochemical industries, coal mines and other scenarios, and can achieve remote data transmission.

4. Material Quality:

The quality of materials used in the construction of gobar gas plants significantly influences their longevity and performance. High-quality materials such as reinforced concrete, fiberglass, and corrosion-resistant metals command higher prices but offer superior durability and reliability over time. Investing in quality materials ensures the longevity and efficiency of the gobar gas plant.

5. Installation and Labor Costs:

The installation and labor costs associated with setting up a gobar gas plant can vary depending on factors such as location, site preparation requirements, and local labor rates. Complex installations or sites with challenging terrain may incur higher labor costs. It is essential to factor in installation and labor expenses when budgeting for a gobar gas plant.

6. Gas Utilization System:

The gas utilization system, including pipelines, burners, regulators, and other components, adds to the overall cost of the gobar gas plant. The complexity of the gas utilization system will depend on the intended use of the biogas, whether for cooking, heating, or electricity generation. Investing in a well-designed and efficient gas utilization system ensures optimal utilization of biogas and enhances user convenience.

7. Maintenance and Operational Costs:

While initial capital costs are a significant consideration, it is essential to account for ongoing maintenance and operational expenses. Regular maintenance, including slurry removal, digester cleaning, and component inspections, helps ensure the continued performance and longevity of the gobar gas plant. Budgeting for maintenance and operational costs is crucial for the sustainable operation of the plant.

Conclusion:

Investing in a gobar gas plant offers numerous benefits, including sustainable energy production, waste management, and environmental conservation. However, understanding the factors influencing gobar gas plant prices is essential for making informed decisions and maximizing the return on investment. By considering factors such as plant capacity, digester design, material quality, installation and labor costs, gas utilization system, and maintenance expenses, individuals and communities can navigate the gobar gas market effectively and choose a solution that meets their energy needs and budget requirements.