In the pursuit of sustainable energy solutions, biogas has emerged as a frontrunner, offering a clean and renewable alternative to traditional fossil fuels. However, to ensure the efficiency and environmental benefits of biogas production, precise monitoring and analysis are essential. This is where biogas analyzer technologies come into play, unveiling a new era of precision in sustainability. In this article, we will explore the significance of biogas analyzer technologies, their functionalities, and the impact they have on advancing the field of sustainable energy.

The Importance of Biogas Analysis

Biogas, typically composed of methane (CH4) and carbon dioxide (CO2) along with trace amounts of other gases, is a product of anaerobic digestion. The composition of biogas can vary based on factors such as feedstock, digester conditions, and microbial activity. Accurate analysis is crucial for several reasons:

- Optimizing Energy Production: Understanding the composition of biogas allows for the optimization of energy production. Methane is the primary component that contributes to the calorific value of biogas, so monitoring its concentration is vital for efficient energy generation.

- Environmental Impact: Biogas is considered a clean energy source, but the presence of certain gases, like hydrogen sulfide (H2S) or ammonia (NH3), can have environmental implications. Monitoring and controlling these elements are essential for minimizing environmental impact.

- Digester Performance: The efficiency of anaerobic digestion, which is the process that produces biogas, depends on various factors. Analyzing the biogas provides insights into the overall performance of the digester, helping operators make adjustments for optimal conditions.

Key Functionalities of Biogas Analyzers

- Gas Composition Analysis: Biogas analyzers precisely measure the concentration of methane, carbon dioxide, and other gases in the biogas mixture. This information is crucial for assessing the quality and energy potential of the biogas. For example, the OLGA2000 biogas online monitoring system can be widely used in gas monitoring in landfill biogas power plants, petrochemical industries, coal mines and other scenarios, and can achieve remote data transmission.

- Continuous Monitoring: Many biogas analyzer technologies offer real-time and continuous monitoring capabilities. This ensures that any fluctuations or anomalies in biogas composition are promptly identified.

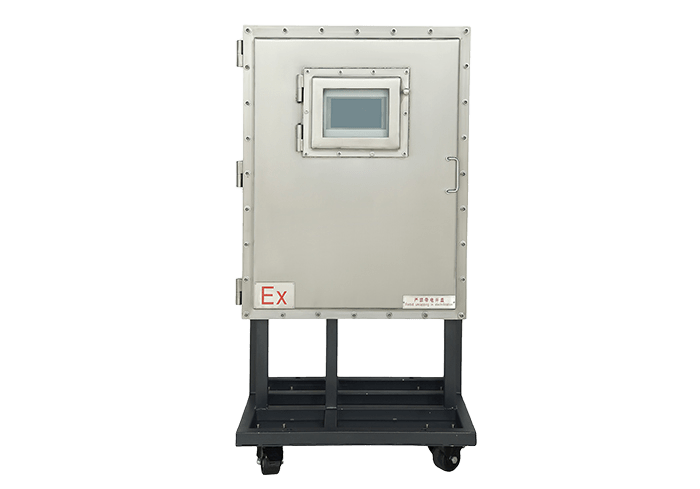

- Durability in Harsh Environments: Biogas production environments can be harsh, with elevated levels of humidity and potentially corrosive gases. Biogas analyzers are designed to withstand these conditions and provide accurate readings over extended periods.

The Impact on Sustainable Energy Practices

- Optimized Energy Yield: By precisely analyzing biogas composition, operators can fine-tune the production process, ensuring maximum energy yield and efficiency.

- Reduced Environmental Impact: Timely detection of trace gases allows for the implementation of measures to reduce or eliminate harmful emissions, minimizing the environmental impact of biogas production.

- Enhanced Digester Management: Continuous monitoring of biogas composition provides valuable insights into digester performance, facilitating proactive maintenance and adjustments for optimal operation.

- Data-Driven Decision-Making: The data generated by biogas analyzers empower operators to make informed decisions, leading to improved overall system performance.

As the world increasingly relies on renewable energy sources, the precision provided by biogas analyzers becomes integral to the success of sustainable practices. In unveiling the intricacies of biogas composition, these technologies pave the way for a future where clean energy production is not just a goal but a precisely measured and achieved reality.