In the quest for sustainable and renewable energy sources, biogas production has emerged as a promising solution. Derived from the anaerobic digestion of organic materials, biogas is a clean and versatile energy source. However, the efficiency of biogas production can vary widely depending on several factors. In this article, we will unravel the puzzle of biogas production efficiency by exploring the key factors that influence its effectiveness.

1. Feedstock Composition

The type and composition of organic feedstock significantly impact biogas production efficiency. Different materials, such as agricultural residues, food waste, sewage sludge, and energy crops, have varying levels of biodegradability and methane potential. A balanced mixture of carbon-rich and nitrogen-rich materials can enhance the overall efficiency of the anaerobic digestion process.

2. Temperature

Temperature plays a crucial role in the efficiency of anaerobic digestion. Biogas production is most efficient within a specific temperature range, typically between 35°C to 55°C (95°F to 131°F). Lower temperatures slow down microbial activity, while higher temperatures can inhibit it. Maintaining the optimal temperature range is essential for maximizing biogas yield.

3. pH Levels

The pH level of the digester environment is another critical factor. Anaerobic digestion is most efficient when the pH is within a neutral to slightly acidic range (pH 6.5 to 7.5). Fluctuations in pH can disrupt the microbial balance, leading to reduced biogas production. Proper pH control is essential for maintaining efficiency.

4. Carbon-to-Nitrogen Ratio (C/N Ratio)

A balanced carbon-to-nitrogen ratio in the feedstock is vital for efficient biogas production. The ideal C/N ratio can vary depending on the specific microorganisms present in the digester. Inadequate carbon can lead to reduced methane production, while excess carbon can result in excess carbon dioxide production. Finding the right balance is essential for optimal efficiency.

5. Retention Time

The retention time, or the duration that feedstock remains in the digester, is crucial for efficient biogas production. Longer retention times allow microorganisms more time to break down complex organic materials fully. However, excessively long retention times can lead to decreased efficiency and require larger digester volumes.

6. Digester Design

The design and configuration of the anaerobic digester can significantly influence biogas production efficiency. Different digester types, such as continuous stirred-tank reactors (CSTRs), plug-flow digesters, and fixed-dome digesters, have unique advantages and disadvantages. The choice of digester design should align with the specific feedstock and operational goals.

7. Inhibition Factors

Inhibition factors, such as the presence of toxic substances or high ammonia levels in the feedstock, can hinder microbial activity and reduce biogas production efficiency. Proper waste separation and pretreatment are essential to minimize inhibition factors.

8. Maintenance and Monitoring

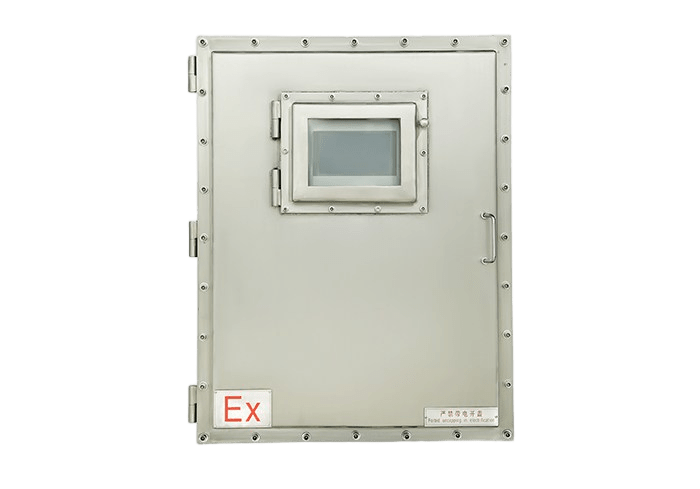

Regular maintenance and monitoring of the biogas plant are crucial for ensuring optimal efficiency. This includes equipment upkeep, pH adjustment, and maintaining proper temperature conditions. Monitoring biogas production rates and the composition of the gas can help identify any efficiency issues early. For example OLGA2000 Online Biogas Monitoring System can be widely used in gas monitoring in landfill gas power plants, petrochemicals, coal mines and other scenarios, and can realize remote data transmission.

9. Gas Storage and Utilization

Efficient storage and utilization of the generated biogas are equally important. Proper gas storage systems, such as gas holders or storage tanks, prevent gas loss and ensure a consistent supply. Efficient utilization of biogas for electricity generation, heating, or vehicle fuel maximizes the benefits of biogas production.

Biogas production is a promising avenue for sustainable energy generation and waste management. However, its efficiency depends on a complex interplay of factors, including feedstock composition, temperature, pH levels, C/N ratio, retention time, digester design, inhibition factors, and maintenance. By carefully considering and optimizing these factors, biogas producers can unlock the full potential of this renewable energy source, contributing to a greener and more sustainable future.