In the realm of sustainable energy solutions,biogas fermenters have emerged as unsung heroes,capable of turning organic matter into a valuable renewable energy resource.These ingenious systems operate through the process of anaerobic digestion,harnessing the power of microorganisms to transform waste materials into biogas—a versatile energy source composed primarily of methane and carbon dioxide.This article uncovers the secrets behind biogas fermenters,exploring their mechanisms,benefits,and the pivotal role they play in converting organic matter into a sustainable energy future.

The Essence of Biogas Fermenters

At their core,biogas fermenters are specialized vessels designed to create optimal conditions for anaerobic digestion.Anaerobic digestion is a natural biological process where microorganisms break down organic matter in the absence of oxygen,resulting in the production of biogas.This biogas can be harnessed for a wide range of energy applications.

Transforming Organic Matter into Energy

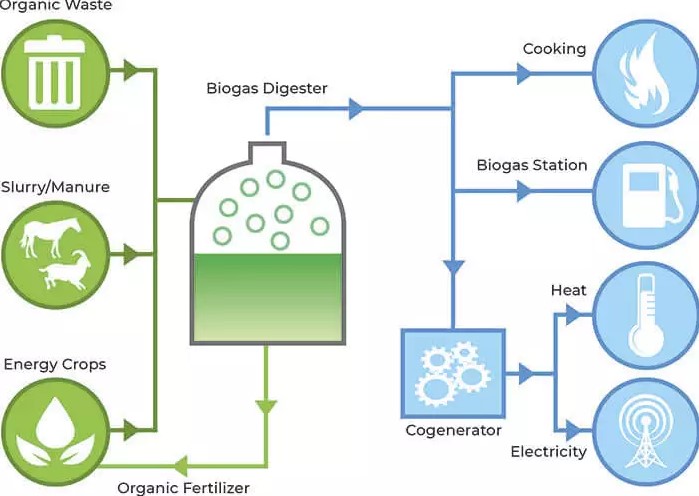

1.Feedstock Collection:Various organic materials,including agricultural residues,food scraps,and sewage sludge,are collected and introduced into the fermenter.

2.Anaerobic Digestion:Microorganisms within the fermenter metabolize the organic matter,producing biogas as a byproduct.

3.Biogas Collection:The biogas generated is collected and can be stored for future use.

4.Energy Utilization:Biogas can be employed for tasks such as cooking,heating,electricity generation,and even as a vehicle fuel.

The Green Advantages

1.Renewable Energy Source:Biogas serves as a renewable energy alternative to conventional fossil fuels,reducing reliance on non-renewable resources.

2.Waste Reduction:By diverting organic waste from landfills,biogas fermenters contribute to efficient waste management and decrease methane emissions.

3.Carbon Footprint Reduction:Utilizing biogas significantly reduces carbon emissions,making it a key player in mitigating climate change.

4.Nutrient Recycling:The residual material after digestion,known as digestate,is a nutrient-rich fertilizer that can enhance soil health and reduce the need for synthetic fertilizers.

Technological Innovations

1.Digester Design:Innovations in fermenter design ensure efficient mixing,temperature control,and waste breakdown.

2.Process Monitoring:Real-time monitoring systems help maintain optimal conditions for microbial activity,enhancing biogas production.

During the biogas production process,the required equipment is a biogas analyzer,which uses advanced photoelectric sensing principles to detect and analyze methane(CH4),oxygen(O2),carbon dioxide(CO2),hydrogen sulfide(H2S)and other gases.For example OLGA2000 Online Biogas Monitoring System can be widely used in gas monitoring in landfill gas power plants,petrochemicals,coal mines and other scenarios,and can realize remote data transmission.

3.Biogas Upgrading:Advanced upgrading techniques refine biogas into biomethane—a higher-quality gas suitable for injection into natural gas grids.

From organic matter to renewable energy,biogas fermenters unlock the hidden potential within waste materials.By tapping into the marvels of anaerobic digestion,these systems provide us with an eco-friendly energy source that simultaneously addresses waste management and energy production.