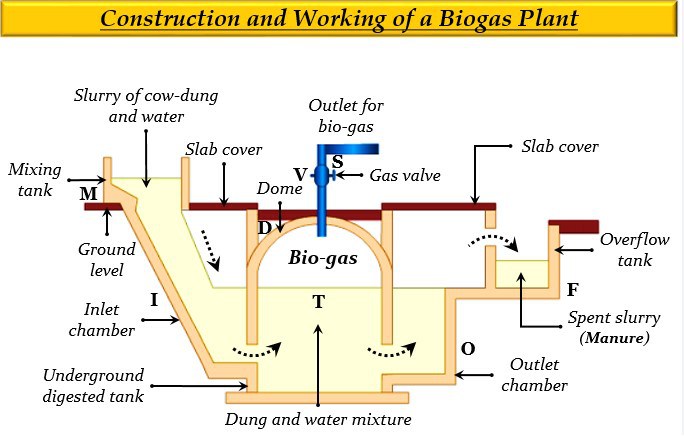

Methane digesters, also known as biogas digesters, are innovative technologies that unleash the potential of biogas production. These systems harness the power of anaerobic digestion to convert organic waste into a valuable renewable energy source—biogas.

At the heart of methane digesters is the natural process of anaerobic digestion, which occurs in environments that lack oxygen, such as wetlands, swamps, and the digestive systems of some animals. Anaerobic microorganisms, such as bacteria and archaea, play a crucial role in this process.

When organic matter such as agricultural residues, food waste, and animal waste is placed in an anaerobic environment, microbes break down complex organic compounds. During this decomposition, microorganisms produce a gaseous mixture, the main components of which are methane (CH4) and carbon dioxide (CO2). This gas mixture is biogas.

Three main stages of anaerobic digestion

Hydrolysis: In the first stage, complex organic compounds are broken down into simpler compounds such as sugars, amino acids, and fatty acids through the process of hydrolysis. This stage is critical because it makes the organic matter more accessible to other microorganisms.

Acid production: In the acid production stage, acidogenic bacteria further decompose the simple compounds produced in the hydrolysis stage and convert them into organic acids, alcohols and hydrogen.

Methane production: The last and most critical stage is methanogenesis, where methanogens use the organic acids, alcohols and hydrogen produced in the previous stages to produce methane (CH4) and carbon dioxide (CO2). Methanogens are strictly anaerobic, meaning they can only function in environments that lack oxygen.

Biogas composition and energy potential

The composition of the biogas produced in the methane digester varies according to the feedstock and the efficiency of the digestion process. In addition to methane (CH4) and carbon dioxide (CO2), biogas may contain traces of other gases such as hydrogen sulfide (H2S) and water vapour. The methane content of biogas is a key factor in determining its energy potential. It is necessary to use a biogas analyzer such as the MGA1000 adopts the advanced photoelectric sensing principle to realize the detection and analysis of methane (CH4), oxygen (O2), carbon dioxide (CO2), hydrogen sulfide (H2S) and other gases. Higher methane content corresponds to higher calorific value, making Biogas is better suited for a variety of energy applications, including power generation and heating.

Energy production from biogas

Power generation: Biogas can be used to fuel internal combustion engines or turbines to generate electricity for various energy needs.

Heat production: The combustion of biogas produces heat that can be used for heating in residential, commercial and industrial environments.

Vehicle fuel: After purification and compression, biogas can be used as an alternative fuel for vehicles to reduce greenhouse gas emissions in transportation.

Combined heat and power (CHP): Combined heat and power systems use biogas to generate electricity and heat at the same time, maximizing energy efficiency.

The science behind methane digesters is a testament to the power of nature to convert organic waste into biogas. When we harness the potential of biogas, we take an important step towards a greener and more sustainable world, where organic waste becomes a valuable resource and renewable energy powers our future.